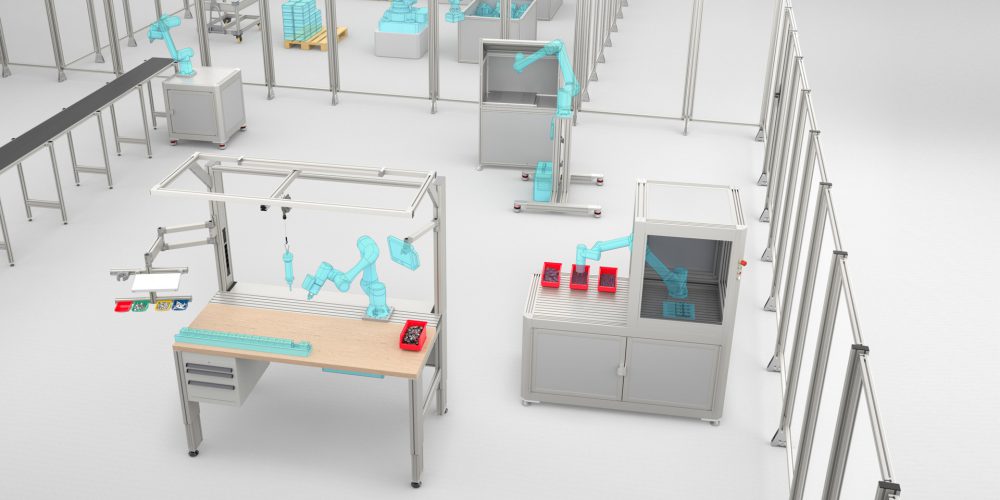

In collaboration with Mobile Industrial Robots (MiR), item is demonstrating the compatibility of AMRs and the item catalogue, including Karakuri, Lean Production, and Work Bench Systems.

The item Blog has previously explored the difference between AGVs and AMRs, presented flexible structure solution designs compatible with AMRs, and examined trends and the future of robotics in manufacturing. At Hannover Messe USA, item had the chance to showcase – in person – the compatibility and versatility of Autonomous Mobile Robots and the item product catalogue.

co-located with IMTS, Hannover Messe USA is “the largest gathering of industrial manufacturing in North America,” delivering a concentrated experience for US manufacturers seeking world-class leading technologies and services necessary to win amid disruption and digitization. In collaboration with Mobile Industrial Robots (MiR), item developed a microcosm of a workflow that was scalable and available for integration across a wide range of industries. Let’s take a closer look at each piece of the workflow:

Big Picture Solutions, Scaled-Down Demonstration

Karakuri Manual Lift

This unit, with a front transfer system driven by the elevator, delivers boxes to and receives boxes from the Mobile Karakuri unit on the AMR.

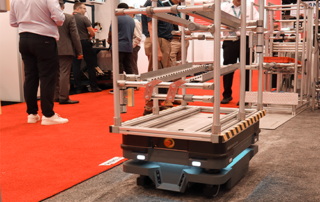

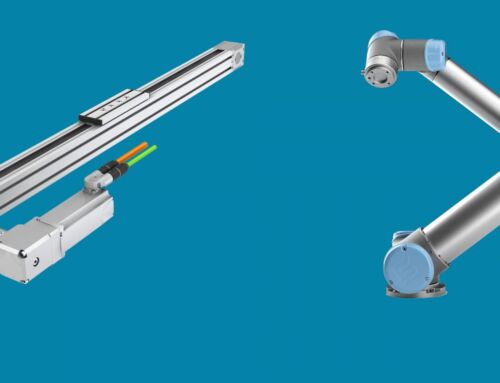

Karakuri Mobile AMR

Mounted securely on the MiR AMR unit, this Karakuri uses a front transfer system to deliver a full box of product while simultaneously receiving an empty box. The MiR unit used was the MiR 250 Shelf Carrier, and this specific configuration for mounting is just one of several solutions developed by item.

Lean Production Workstation

From the Spring 2022 new product selection, this lean production workstation has ergonomic height adjustment without electricity. Using a crank, the workbench can be raised to meet specific users’ heights thanks to Table Column Set K. For the HMUSA Show, additional work bench accessories included tool holders, thin client holders, and monitor holders that allowed the item team to showcase new practical functions in the item Engineeringtool.

Height-Adjustable Work Bench System

With all the bells and whistles, this ergonomic work bench provided a ‘second take’ on the ergonomic work bench made from the D30 product line. This work bench uses electricity to provide an ergonomic workspace, lowering or raising the desktop to suitable heights. This unit came complete with a monitor arm, thin client holder, whiteboard, and plenty of item toolpanel® accessories for organization.

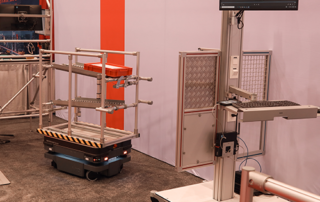

Karakuri Receiving Unit

While delivering the full box of product, the AMR activates mechanisms to simultaneously receive the empty box and blocking the lowering system. When the AMR withdraws from this unit, the system is unlocked. This allowed one empty box to leave the unit while a new box of product was brought towards the height-adjustable work bench system.

The booth at Hannover Messe USA was nowhere near the size of an entire manufacturing facility, but the scaled-down workflow provided a demonstration in close quarters of what could be expanded to cover an entire floor, let alone an entire multilevel facility. With over 120,000 attendees, the eye-catching movement of the MiR AMR and Karakuri units provided the backdrop to item Experts sharing knowledge on everything from the specific profiles used in each solution to how the workflow could be personalized, adjusted, and integrated into existing workflows or created to stand alone.

Interested in Mobile Robot Deployment?

Flexible, scalable AMRs can be used in almost any industry – they’re less expensive and typically easier to deploy than traditional automation, and can work safely alongside employees. A well-planned approach makes it much more likely you’ll reach your desired destination quickly and painlessly. Our collaborators over at MiR have created this ebook as a guide to feeling more confident in each stage on your automation journey with AMRs.

Did you attend Hannover Messe USA/IMTS but miss the chance to see the demonstration in person? Let us know! Interested in learning more about robotic applications with item products? We’re consistently publishing and sharing the latest articles online, so subscribe to the item blog by completing the box at the top right to ensure you don’t miss any of the latest industry-leading info!