Right to repair – what does it mean for companies?

Repairing instead of throwing away – the “right to repair” is just around the corner. But what does that mean for manufacturing and refurbishing? And what is the best way to design a work bench for repair work? We asked our experts for you.

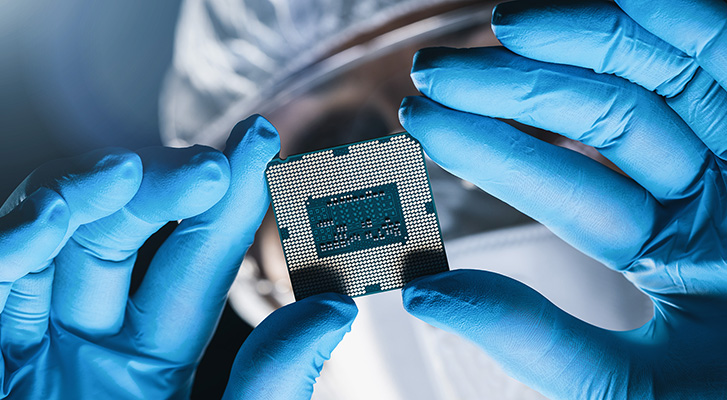

Can you picture 35 million metric tons of waste? To put that into perspective, every person on earth (around 8 billion) would have to own around 22 smartphones to produce this amount of waste. That is a lot. That’s also how much waste is produced in the EU every year, and almost five million metric tons of it is electronic waste. Consider this: How long is it before your smartphone stops working the way it should and seems to completely give up? When a device develops a fault, getting it repaired can often seem impossible or uneconomical. This is a common problem. A new law is set to change that – the right to repair. This law raises many questions: What exactly is the right to repair? Which products does it apply to? And what does it mean for companies?

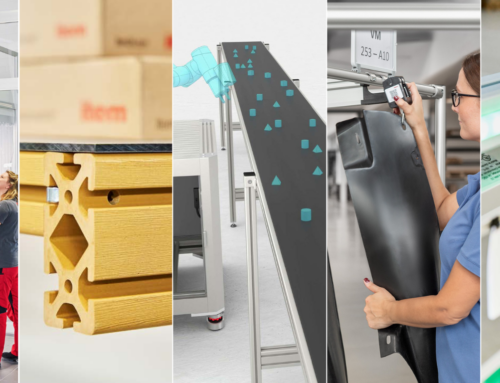

One thing’s for sure – anyone looking to repair products in the future will need to have the right kind of work benches to carry out the necessary working processes. If you don’t have your own repair shop yet, a whole host of new business opportunities are opening up. And that’s the key factor, as our work bench expert Marius Geibel explains.

Work Bench System from item

Ergonomic, efficient and expandable – the Work Bench System from item offers the ideal solutions for manual production tasks.

What is the right to repair and which products does it apply to?

“The right to repair is a new EU directive: The associated proposal came into effect on 1 July 2024. The EU member states now have two years to integrate it into national law. The deadline for this is 31 July 2026. This new directive requires companies to repair their products even after the statutory warranty period has elapsed.

This is intended to promote repair over replacement. After a repair, the statutory warranty period is then extended by one year. On top of that, consumers must be provided with replacement devices, tools and repair information. The aim of the new directive is to extend product service life and reduce electronic waste.

The right to repair is designed to extend product service life and reduce electronic waste.

The right to repair will initially apply to household appliances, consumer electronics and IT products (e.g. washing machines, vacuum cleaners, smartphones, welding equipment and servers). The list of affected products is set to continuously expand. The long-term objective is to cover as many devices and appliances as possible. And what does that mean for consumers? They benefit from lower costs and a longer product service life.”

What does the directive mean for manufacturing?

“Manufacturers now have to offer repair services. They can do that directly, through service companies or through independent workshops. When manufacturing products, companies must ensure that these products can actually be repaired. For example, lots of people have found that replacing the battery in their smartphone is virtually impossible. In future, devices must be designed so they are convenient to repair. Similarly, spare parts must also be made available to consumers, and information relating to repairs must also be more readily accessible.

When manufacturing products, companies must ensure that these products can actually be repaired.

The law provides for an extension of the statutory warranty after a repair. This is a huge benefit for consumers, allowing them to enjoy their devices for longer. In addition to cost savings, the law contributes to sustainability, conserving valuable raw materials and reducing electronic waste. Some countries and federal states are supporting these measures financially. This gives manufacturers an additional incentive to adapt quickly. However, manufacturers only have a transition period of two years, which is a very short time frame for a product development cycle.”

What do you need to bear in mind when designing repair work benches in workshops?

“A repair work bench must be designed efficiently and ergonomically. Unlike in production, the focus here is on tools and rapid access to information. An ideal work bench will help users lay their hands on all the necessary tools, a wide range of spare parts and instructions in next to no time, ensuring users are adding value every time they reach for something.

A repair work bench must be designed efficiently and ergonomically. Unlike in production, the focus here is on tools and rapid access to information.

This is where the item Work Bench System can reach its full potential. It allows for the structured arrangement of tools in a very small space, with efficient information systems supporting employees in their work. Ergonomic design principles ensure that employees remain healthy and productive. A tidy and well-organised environment is crucial when it comes to repairing products.”

The item Work Bench System is ideal for repair workstations.

How can production companies benefit from optimised work bench design?

“The new right to repair presents manufacturers and refurbishment companies with another set of challenges. Competition is becoming more intense, making the health of employees more important than ever. This is where an optimised work bench design can make all the difference. A well-equipped work bench with the right tools and fast-acting systems for providing information increases efficiency and reduces costs.

The item Work Bench System offers custom solutions specifically for repair work.

The item Work Bench System offers custom solutions specifically for repair work. Ergonomically designed work benches promote health and productivity in employees. In addition, efficient processes help boost the competitiveness of companies. The right to repair offers manufacturing and refurbishment companies an opportunity to optimise their processes and improve customer satisfaction and loyalty.”

What experience does item have providing work benches for repair workshops?

“item has extensive experience in providing customer-specific work benches for repair work. This experience really stands out when it comes to high-value devices. One notable example is our collaboration with Olympus Medical Products Portugal, which is now repairing and maintaining endoscopes in a new repair facility. We customised over 200 work benches to meet the specific needs of staff. The new facility covers over 1000 m². Repairs can now be carried out at Olympus with the utmost efficiency and to the highest standard.”

What is your personal takeaway from the new directive?

“This new law is a big step in the right direction. It benefits both customers and the environment by extending product service lives and conserving resources. I like to repair things myself. You get a real boost from giving a faulty product a second life. If this becomes mandatory, people and the environment will benefit in equal measure.

This new law is a big step in the right direction. It benefits both customers and the environment.

I hope that the law doesn’t have any major loopholes and will go on to cover as many products as possible. Businesses are clearly under pressure, and adapting could be a challenge. It will be interesting to see how they respond to this and whether new service companies emerge. All in all, I see the law as a crucial step towards sustainability and resource conservation.”