A guard for industrial use must have a compliant design. Read on for details of the relevant US regulatory and technical requirements.

In the United States, machine safety is regulated primarily under the Occupational Safety and Health Act and the associated OSHA regulations (29 CFR 1910). Only machinery that is designed, installed, and operated in a safe condition may be used in production environments.

A risk assessment – commonly performed in accordance with ANSI B11.0 (Safety of Machinery – Risk Assessment and Risk Reduction ) – helps determine whether a safety guard is required. If design measures alone are not sufficient to reduce hazards to an acceptable risk level, physical guarding or safeguarding devices must be implemented.

Key consensus standards commonly used when designing safety guards in the US include:

- OSHA 29 CFR 1910 Subpart O (Machinery and Machine Guarding)

- ANSI B11.19: Performance criteria for safeguarding

- ANSI B11.0: Risk assessment and risk reduction

- ANSI B11.20: Safeguarding on integrated manufacturing systems

- ANSI B11.6 / B11.8 / B11.11, etc., depending on machine type

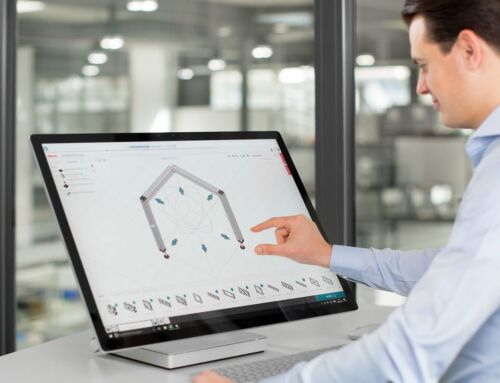

item has designed its configurable guard elements to support compliance with these US requirements. Using the Online Shop and the item Engineeringtool, you can customize safety guards to your application while supporting OSHA and ANSI conformance.

What is the link between US machine safety regulations and the design of safety guards?

Unlike the European Union, the United States does not use CE marking or the Machinery Directive. Instead:

- OSHA regulations (29 CFR 1910) are legally enforceable

- ANSI B11 standards are voluntary

- OSHA frequently references ANSI standards when assessing compliance and determining “recognized hazards.”

According to 29 CFR 1910.212(a)(1), machinery must be equipped with guarding to protect operators and other employees from hazards such as point of operation hazards, ingoing nip points, rotating parts, flying chips and sparks. A machine typically requires a safety guard to meet these obligations. A documented risk assessment per ANSI B11.0 helps determine whether fixed guards, interlocked guards, or other safeguarding methods are appropriate.

If design measures alone cannot adequately control risk, additional safety guards must be installed in accordance with applicable OSHA requirements and ANSI standards.

Key considerations when designing safety guards

Key considerations when designing safety guards

In the item Academy, you’ll find detailed information about what to bear in mind when designing guards. The relevant online training module sets out the key considerations step by step.

What are the requirements when designing a safety guard?

ANSI B11.19 is the primary US standard governing the performance criteria for safeguarding. It outlines requirements related to:

- Mechanical strength and durability

- Resistance to impact

- Protection against circumvention or tampering

- Visibility of the hazard zone

- Secure attachment and positioning

A safety guard must prevent personnel from reaching or entering hazardous areas during machine operation. If solid panels are used, the guard may also provide protection against ejected parts, splashing liquids, emissions, or other byproducts of the manufacturing process.

What impact loads must a safety guard withstand?

US standards do not specify a single universal impact value (such as joules) but ANSI B11.19 requires guards to withstand reasonable and foreseeable impact loads without permanent deformation or loss of protective function. This includes:

- Accidental contact by personnel

- Incidental impacts from carts, tools, or material handling equipment

- Forces generated during normal machine operation.

For higher-risk environments, such as automated lines or automotive production, manufacturers often specify enhanced impact resistance. item offers guard solutions designed and tested for high robustness, including systems capable of withstanding extreme impact conditions.

When using Clamp Profile 8 40×40, panel elements are securely fastened to the profile, producing guard systems suitable for applications requiring exceptional rigidity and durability.

Protection against tampering under ANSI B11.19

ANSI B11.19 requires safeguarding systems to be designed so they cannot be easily bypassed, removed, or defeated. If removable or detachable guard panels are used for maintenance purposes:

- Tools must be required for removal

- It must be immediately apparent when the guard is no longer in place

- The guard must not continue to provide a false sense of protection once removed.

The item Safety Hanger supports these requirements by creating a visible and functional change as soon as panels are detached, clearly indicating that safeguarding has been interrupted.

Interlocking devices and ANSI B11 requirements

When access doors are installed in safety guards, OSHA and ANSI require that machine safety be maintained during access. ANSI standards distinguish between:

Simple interlocks: suitable when opening a guard causes the machine to stop immediately

Interlocks with guard locking: required when the machine has a stopping delay, hazardous motion persists after power removal, and controlled access is required during production or inspection

Interlocks with guard locking help ensure that the machine cannot be accessed until hazardous motion has ceased – or, alternatively, that the machine does not stop when intentional access is part of the operational process, such as quality checks.

Safety distances and reach prevention in US standards

US safety standards use principles that closely align with ISO 13857, but they are implemented through ANSI B11.19, ANSI B11.20, and OSHA’s general duty to prevent access to hazards.

Correct safety distances depend on the height of the guard, size of openings, location and size of the hazard, and the expected reach of hands, arms, or tools.

Larger mesh openings or lower guard heights require increased distance from the hazard source. Conversely, higher guards restrict reach and allow guards to be positioned closer to the hazard.

The item corrugated and steel mesh panels with a 4mm mesh width help prevent limbs from passing through the guard, supporting compliance with recognized reach-prevention criteria. A fixed lower clearance of 170 mm is used to reduce access under the guard in typical industrial environments.

How item supports OSHA- and ANSI-compliant safety guard design

All safety guard components in the item portfolio undergo mechanical testing to verify durability and impact resistance. This allows you to design robust guarding solutions with confidence.

Ready-made guard elements simplify the design process

The item Online Shop configurator automatically selects compatible components

The item Engineeringtool enables full guard system design and integration.

Together, these tools help you develop safety guards that support compliance with US regulations and recognized industry standards.