When used in combination, the item Suspended Conveyor System and AMRs from Peer Robotics offer manufacturing companies an innovative solution for efficient material supply.

Time is money! This famous saying credited to Founding Father Benjamin Franklin is truer than ever in today’s fast-paced industrial environment. Throughput times need to be reduced, waiting times need to be avoided. All of that makes smooth material supply processes essential. Materials must be available at all times so staff don’t experience any disruption when carrying out work that actually adds value. However, this poses a constant challenge in branches of industry such as the automotive and electronics sectors, where materials need to be efficiently transported between the warehouse, production line and dispatch section. Combining the item Suspended Conveyor System with the learning-capable AMRs (autonomous mobile robots) of robot manufacturer Peer Robotics offers an innovative solution to this challenge.

Collaborative AMRs for easy integration and handling

Driverless transport systems such as AMRs are playing an ever greater role in material transportation. As their name suggests, AMRs operate autonomously and can navigate unregulated surroundings, meaning they don’t rely on fixed routes or tracks. To find their way around, AMRs generally use maps that are either created on site by the robot’s software or uploaded onto the robot in the form of a floor plan. With the aid of integrated cameras, scanners and sensors, the autonomous robots automatically calculate the shortest route to their destination. If that destination changes, a new map needs to be programmed accordingly.

Peer Robotics takes a different approach, however, and specializes instead in collaborative autonomous mobile robots with integrated intelligence. Thanks to the patented Person2Peer technology, the robot can learn from people in real time. “Our mobile robots can understand if a human is applying a force to the robot. Once the robots recognize that a human is applying force feedback, they switch to learning mode, so they can learn about the external environment and the path the user wants the robot to take in,” explains Rishabh Agarwal, co-founder of Peer Robotics. This means these mobile robots, fitted with various superstructures, can be used easily and flexibly for a huge range of working processes.

Efficient transportation of bulky and suspended materials

Peer Robotics currently offers solutions for moving around trolleys, containers and pallets. You can use these AMRs to automate processes such as kitting, material infeed and the placement of finished products in storage. Now, thanks to the item Suspended Conveyor System, this range of capabilities is being further extended to include a new innovative solution for material supply. “This is a combination not used in any market yet,” says Ben Hull, Director of Sales at item. This offers huge potential, particularly for the automotive and electronics industries. Moving around materials such as ESD mats, cable harnesses and large automotive parts uses up a lot of space and requires human intervention, all of which can potentially generate waste. By contrast, our Suspended Conveyor System enables space-saving and efficient transportation. What’s more, when combined with the mobile robots from Peer Robotics, it offers you a fully automated, end-to-end solution.

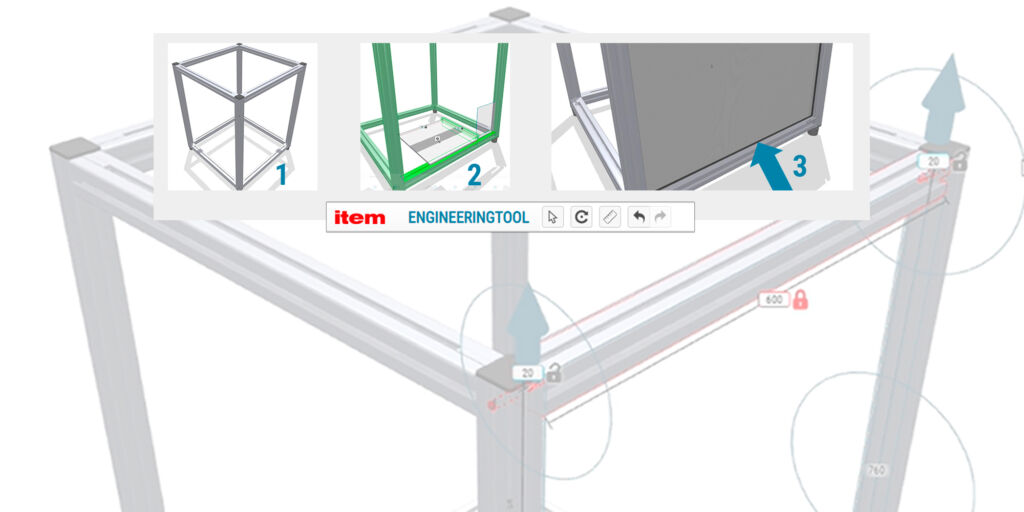

The item Suspended Conveyor System is particularly suitable for parts that are too large for small load carriers (SLCs) or that can easily become entangled. Components such as cable harnesses and mats can be hung up or placed in bags for optimum material supply, slotting them onto a Conveyor Rail Profile using a specially designed Carriage. This Conveyor Rail Profile, which is fitted at a slope of just 3°, ensures the goods being transported glide directly to the removal point by gravity alone. The Carriage is ESD-safe, designed to resist tipping and self-locking, and compensates for swaying motions. The Conveyor Rail Profile is easy to install at the desired height and with the preferred slope in a frame made of Profiles D30 or any other pre-existing frame.

Maximum design freedom with Peer Robotics and item

“After looking at the innovative design platform and all the solutions that item offers to manufacturing companies, it was clear that a collaboration would lead to significant benefits for our customers,” explains Agarwal. The item Suspended Conveyor System is only the start of the collaboration between item and Peer Robotics. Another superstructure, or Top Module, is already being planned. “The next will be an automatic delivery system that operates between the top module on an AMR and a stationary rack (receiving system) within a facility,” says Hull. In fact, there are no limits to what can be achieved when designing Top Modules.

The plan is for the AMRs from Peer Robotics to be compatible with all item Top Modules in future. “We offer our mobile robots as a platform and we are making our robots compatible with existing lean manufacturing modules from item. This enables us to focus on the platform, with users getting the top module they need directly from item,” Agarwal explains. Thanks to the modular building kit system principle, our components can be used to build Top Modules for a whole range of requirements. The choice of profile determines the payload that can be carried. When moving around boxes and SLCs, it is advisable to use lightweight profiles such as those in Profile Tube System D30. If heavy parts need to be transported, it is best to use our item Building Kit System. Moreover, the end-to-end compatibility of our components means that both types of profile can be used together. When combined with the versatile AMRs from Peer Robotics, the end result is material supply solutions for automated production that are geared to specific requirements.