Cable conduits for industry – the basics and practical tips

Although cable conduits are also found around our homes, it’s only in industrial applications where they can truly realise their full potential.

Practically every industrial workstation needs power, and particularly in machine cabins or process enclosures. Depending on the task at hand, there may also be additional requirements, such as supplying compressed air or routing data lines (network connections, cables for sensors, etc.). Cable conduits protect cables from mechanical damage, dust and moisture. They also make it easier to lay cables, thanks to their well-organised structure, with cables deliberately grouped together in separate strands to prevent signal interference, for instance. Depending on your particular needs, the supply lines are routed above or below the working surface. They are also quick to install and can be modified at any time, ensuring maximum flexibility. At the same time, our high-quality cable conduits prevent possible trip hazards and cable clutter, while also leaving your workstation looking just right. This is where that combination of form and function that is such a key feature of the item world really shines. Our cable conduits offer a large selection of weight- and size-optimised variants made of aluminium or plastic. But what different ways can cable conduits be used in industry? And which variant is right for which scenario?

Custom solutions for your cable management

Find the right solution in the item Online Shop. Using our conduit systems, you can route cables so they are out of sight and safe from dust. Run cables and supply lines like a pro!

Profile technology and accessories for optimising all types of supply lines

When cable conduits for industrial applications need to be fit for a specific purpose, it is advisable to use special profiles. For instance, there are profiles with an integrated conduit, which are ideal for building frames complete with cabling, ensuring the cables are safely covered over inside the profile. When it comes to designing machine cabins, our Line XMS with integrated cable conduits offers exceptional flexibility, saving you the hassle of planning additional conduits.

There are three distinct conduit systems: Conduit System K (made of plastic), Conduit system E and the Modular Conduit System (both made of aluminium).

Thanks to their versatility, our conduit systems cover a particularly wide range of applications. The Conduit Profiles and Lid Profiles form the basis of any system. Special inside-corner pieces, meanwhile, help stop kinks developing in cables as they branch off in different directions through industrial conduit systems. They also cover over sharp, cut edges. These components combine to create versatile, dust-proof conduits for laying cables and lines. Our conduit systems are available in various sizes and materials, and come in three distinct conduit systems: Conduit System K (made of plastic), Conduit system E and the Modular Conduit System (both made of aluminium). Universal Holder 8 K, Retainer is a particularly time-saving solution.

A guide to choosing the right cable conduit – which solution for which requirement?

When choosing the right cable conduit, the type, quantity and diameter of the cables are all important factors. Plastic conduits are lighter and easier to cut to size than their aluminium counterparts. On the other hand, aluminium conduits are more stable and heat-resistant and offer a high level of electromagnetic shielding.

Conduit Profile U 80×80 K, grey from Conduit System K.

Conduit System K (plastic)

The Conduit Profiles from Conduit System K are made of plastic. The profiles are fixed in place directly in the Line 8 profile groove using a special clip. They are available in two widths and heights. Conduit System K has been designed to match the contour of Profiles X 8 and complements the integrated cable conduits of Line XMS profiles. By using our swivel-in Catches, you can prevent cables from slipping out of Conduit Profiles K – even when they are installed vertically or overhead.

The benefits of Conduit System K at a glance:

✔️ Made of lightweight plastic

✔️ Easy to fasten to Line 8 profile grooves

✔️ Perfect complement to the integrated cable conduits of XMS profiles

Conduit Profile U 160×80 SE, natural, from Conduit System E.

Conduit System E (aluminium)

U-shaped conduit profiles with matching covers form the basis of Conduit system E. These simple aluminium conduits are available with or without a screw channel (profiles with SE in their product name incorporate screw channels) for attaching metal Caps to the ends. Choose between conduits in five widths and six heights in the modular dimensions of Lines 6 and 8. The range of possible applications is equally broad. For example, Conduit Profiles U from Conduit System E can be used to create a cable conduit measuring just 30 x 15 mm. However, they can also be used to build a 160 x 160 mm cable duct. Use Cable Entry Protectors combined with suitable profile cut-offs to create sealed openings that will allow cables to pass through safely – precisely where they are needed.

The benefits of Conduit System E at a glance:

✔️ Large selection: Conduits in five widths and six heights

✔️The installation of end caps simplifies handling

✔️Wide range of possible applications

Example application for Conduit Profile U 80×80 SE, natural, from Conduit System E. Custom machining makes it possible to attach electronic modules.

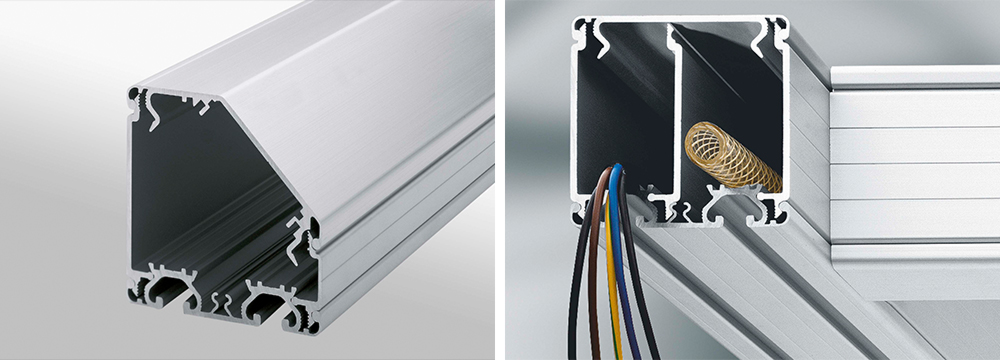

Modular Conduit System with Support Profile 80-45° (left) and Support Profile 80 with grooves 8 and partition made from Wall Profile 80 (right).

Modular Conduit System (aluminium)

The highly versatile Support Profiles with or without Line 8 grooves form the base and cover of the Modular Conduit System. Combining them with Wall Profiles makes it possible to achieve conduit sizes from 40 x 40 mm to 160 x 160 mm in various shapes. Assembly is straightforward, as the Wall Profiles are simply swivelled into the Support Profiles. Angled Support Profiles are ideal for incorporating operating consoles with integrated switches and outlets directly into the cable conduit. The Conduit Inside Corners provide an extra three levels of safety when running cables. First, the cables and lines are protected from kinks. Second, covering the cut edges on the inside provides additional protection for the cables. And third, creating a flush-fitting transition between Wall Profiles and Support Profiles protects employees’ hands. Wall Profiles can be used to create partitions within the cable conduit profiles.

The benefits of the Modular Conduit System at a glance:

✔️ Conduit sizes from 40 x 40 mm to 160 x 160 mm in a variety of shapes

✔️ Easy to assemble, as Wall Profiles are simply swivelled into the Support Profiles

✔️ Suitable for operating consoles with integrated switches and outlets on the cable conduit

You can see the Universal Holder 8 K, Retainer, here.

Universal Holder 8 K

Are you looking for a time-saving way to fasten cables and lines? Then the Universal Holder 8 K, Retainer is the ideal solution. It provides a three-part system for enclosed cable guidance along a groove, whereby the Holder is simply twisted into a Line 8 groove. You can simply push cables up to 13 mm in diameter into the Retainer. Next, clip the 40×20 Lid Profile along the entire length and seal the ends with caps. This way, you can easily create a compact cable conduit in the relevant modular dimension with custom outlets. Cable ties can be used for added security.

Benefits of Universal Holder 8 K at a glance:

✔️ System for quickly installing compact cable conduits

✔️ Simple clip-on design as a key feature

✔️Optional cable ties for added security

Multifunctional supply point for power, network access and compressed air

We have also developed the item Installation Column. The large Installation Column Profile 8 160×160 K76 features two generous cable conduits and integrated aluminium ducts designed to carry compressed air. The opening on the cable conduits also accommodates Mounting Boxes, Sockets, Keystone Modules and Switches, which are simply clipped into place, with no need for machining. You can build a whole array of different Installation Column solutions using these profiles. Think of them as multifunctional supply hubs or as integral parts of machines and workstations. Virtually any work bench can be customised by positioning plug sockets and compressed air connections as needed. For example, an Installation Column can be integrated directly into a safety guard, allowing for the integration of an emergency shutdown system and fixings for emergency equipment such as fire extinguishers.

Getting power and data to where it is needed

Whether it’s for power and data supply or integrating a compressed air supply – the Installation Column can provide the perfect solution to suit your needs.

More than just a cable conduit – Installation Columns in industry

Practical examples make the vast potential of the Installation Column even clearer. A variant we call the Supply Solution is the ideal option for providing the all-round essentials in industrial workshops and logistics facilities. It boasts a securely integrated compressed air duct and incorporates 230- and 400-Volt sockets. By contrast, the Logistics Solution is geared entirely toward the challenges that logisticians meet on a daily basis. Attachments ranging from a Monitor Arm to a Tablet Holder ensure materials and data are always close to hand. The Line 8 system groove on the column offers an adaptable fixing option for a whole range of additional accessories from the item Building Kit System.

The Installation Column is also ideal for use in areas where there are increased safety risks. This includes, for example, production plants, conveyor systems and milling and sawing environments. This is where the Safe Solution comes into its own. Safety elements such as status lights can be integrated into it with ease. The same is true for accessories such as buffers and emergency shut-off buttons. Frames and holders can also be used to attach safety notices and emergency equipment.

The Data Solution provides a central access point for email, internet and intranet when employees in industrial production areas and workshops don’t have their own permanent online access or PC workstations.

Employees in industrial production areas and workshops who don’t have their own permanent online access or PC workstations are at a disadvantage. The Data Solution provides a central access point for internet and intranet. A Monitor Arm and a Pivot Arm for keyboards make working life significantly easier. The Horizontal Solution can be used to integrate switches and power and data sockets neatly into a work bench. For example, control circuit devices can be installed in direct proximity to machines. Installation Profile 160× 80 K76 from item can also be used as wall trunking or built directly into industrial work benches.