Reflecting on a year of game-changing item innovation.

2025 was a landmark year for item America, as showcased here on the item Blog. From game-changing automation insights to sustainability breakthroughs and design innovation, the stories published throughout the year showcased a glimpse into the incredible momentum shaping American manufacturing. As more companies look to modular engineering, digital workflows, and flexible production environments, item has continued to support engineers, integrators, and innovators with new tools, expert guidance, and forward-thinking solutions.

Let’s explore the year’s defining articles and themes from item:

Innovation across industries

The year kicked off with strong attention on cleanroom technologies, a focus area that continues to grow as life sciences, medical research, semiconductor production, and food industries demand safer, more controlled environments. Our feature on cleanroom construction solutions highlighted how modular cleanroom tents, laminar-flow workbenches, and walk-in cabin systems help US manufacturers scale projects quickly and adapt to evolving requirements.

Alongside these environmental solutions, readers were introduced to new ways to accelerate engineering workflows using the item Engineeringtool. Traditional CAD methods can be cumbersome and expensive, but the Engineeringtool offers a streamlined, browser-based alternative that allows teams to design, document, and configure assemblies far more efficiently. We’ve explored how this tool helps engineers reduce development time and eliminate repetitive design tasks.

The rise of advanced automation

Automation remained a central theme throughout 2025, with high-impact features breaking down the complexities of robotic and linear automation strategies paired with the innovation of item.

We’ve studied robotics and linear technology, offering a decision-making framework when comparing these two major automation pathways. Manufacturers looking to optimize their processes were guided through factors such as precision needs, payload requirements, integration constraints, and total cost of ownership. Our guide became a particularly valuable resource for small- and medium-sized US companies evaluating their first steps into advanced automation.

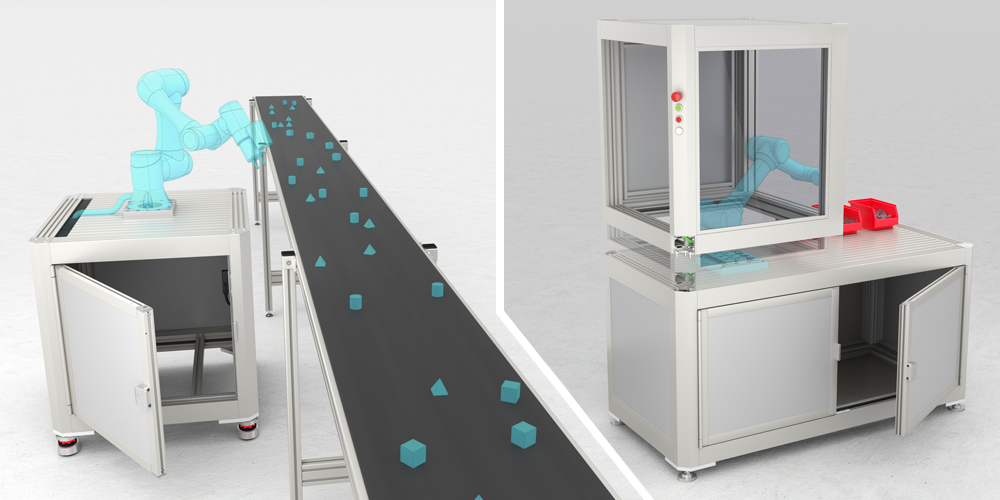

Readers of the item blog also explored new possibilities in materials handling with a detailed introduction to the item Conveyor Belt System. Designed to improve the movement of components and small load carriers, this modular conveyor solution offers the flexibility and standardization today’s facilities require to remain competitive. The system’s adjustability, scalable design, and compatibility with other item components resonated strongly with readers seeking modern intralogistics solutions.

Further complementing the automation landscape was an article on planning mobile industrial robot systems, which provided a practical overview of key considerations when integrating AMRs into manufacturing or warehouse settings. Topics included navigation platforms, safety zones, handling attachments, and the critical role of peripherals. This guide equipped engineers with the foundational knowledge needed to deploy mobile robot fleets confidently and effectively.

Engineering for high-tech sectors

The item Blog also delivered significant content for high-precision industries, including semiconductors, optics, and electronics manufacturing.

A popular article on semiconductor manufacturing requirements highlighted the strict cleanliness, precision, and safety demands associated with chip fabrication. It demonstrated how modular factory equipment must support controlled environments and facilitate repeatable, contamination-free workflows.

Similarly, our spotlight on optical manufacturing highlighted the need for vibration-resistant, contamination-controlled, and ergonomically-optimized factory equipment. The modular building kit principles championed by item were shown to be particularly effective for these sensitive production lines.

We’ve also demystified Electrostatic Discharge (ESD), breaking down what ESD is, why it matters in electronics handling, and which precautions industrial environments must take. This breakdown serves as an accessible technical primer, exploring ESD-safe components and workstations.

Finally, a feature on LED strip controllers demonstrated how industrial-grade lighting control can be implemented even by users with no prior programming experience – a major win for small facilities seeking professional, segmented lighting solutions without steep learning curves.

Award-winning design and engineering excellence

One of the year’s early highlight announcements celebrated the iF DESIGN AWARD 2024, earned by the item Suspended Conveyor System. Our feature explained how the design combines reliable material flow with clean aesthetics and ergonomic benefits, creating an ideal example of engineering meeting form and function. This award underscored item’s global leadership in industrial design and innovation.

Sustainability takes center stage

Sustainability was a defining theme in the latter half of the year, with an introduction of the newest products for 2025. This included the sustainable WFC Profiles. Manufactured from 75% recycled wood fibers and 25% recycled polymer materials, these composite profiles – compatible with the entire item Building Kit System – demonstrate how structural strength and environmental responsible can coexist. Their applications, recyclability, long-term durability, and role in supporting circular manufacturing were spotlighted in a new products highlight.

Looking ahead to 2026

As 2025 comes to a close, item Experts are grateful for your time and dedication spent visiting the item Blog. We hope this vibrant hub for industry insights, modular engineering knowledge, application stories, and product innovation has been beneficial for you. With the continued evolution of automation, sustainability, digital engineering, and precision manufacturing, readers can expect even more innovation in 2026.