item America Hosts First-Ever Open House

Visitors from regional businesses stop in to see item America’s headquarters in action.

On Tuesday, September 10, item America opened its doors to customers for its first-ever open house. With expert-led training sessions, facility tours, item Roadshow displays and delicious breakfast and lunch offerings, there were plenty of reasons to attend.

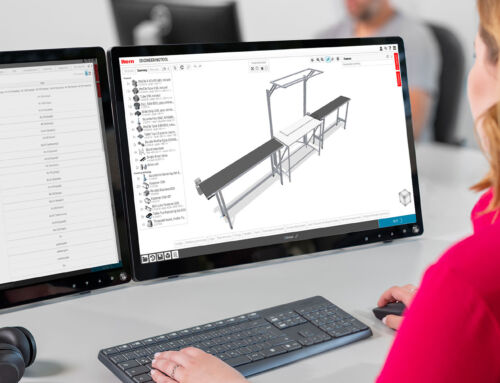

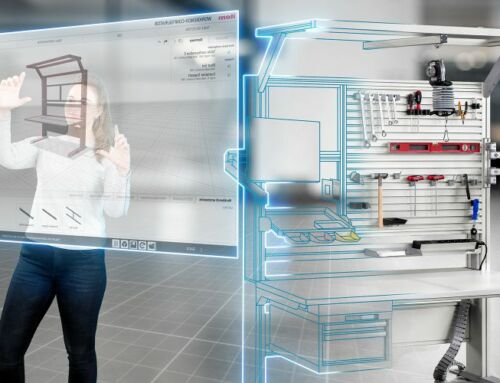

Expert Training

By far, the most popular activities were the trainings. Lead Engineer Brian McDonald led an informative session on navigating the item Engineeringtool. item’s Engineeringtool is a free-to-use, fully functional design and engineering tool that gives the user the flexibility to design their own solutions without any CAD (Computer Aided Design) experience. Brian demonstrated how the program works and showed a real project from start to finish. A guest was heard commenting, “I can’t believe you are offering this program for free!” The second training focused on assembly with item America’s Team Lean lead, Tim Coy. Tim showed his group a generous mix of profiles and connectors and how to use them for many applications, including industrial fencing and guarding, structural frames and more.

Tours and Displays

In the item America showroom, visitors found an impressive karakuri display. For the uninitiated, karakuri is an age-old Japanese engineering novelty that grew to have real-world uses. In essence, karakuri uses natural forces like weight, gravity and inertia to move an object. While the first were just toys, they now help keep production lines moving without any external power source! The item showroom display offers an example of many different karakuri methods in one solution. The visitors loved it!

Visitors also seemed particularly interested in the facility tours. Depending on the guide, some tours offered glimpses into different parts of the manufacturing and warehouse facility. Many of the attendees enjoyed multiple tours with different guides to optimize the experience!

Another “hot” display was DVF Corporation’s air-powered hot glue manufacturing robot. When a visitor first walked in the front door, they found a working robot on display, proudly built on an item machine base! DVF President, Jay Wolfe was excited his team (and robot) were able to be part of the open house. Guests were fascinated by the precise technology of the robot design and its sturdy, mobile base.

All in all, it was a worthwhile day for everyone. item encourages anyone interested in hands-on configurator or assembly training to consider getting in touch with their regional salesperson to set up an appointment; visitors are welcome any day of the year!