How Lenkering GmbH found an innovative solution to a long-standing problem.

Custom assembly work benches are perfectly adapted to the steps in the relevant process. One inevitable downside of this, however, is their inflexibility, with a typical annual capacity utilisation of between just 20 and 40 percent. That leaves a lot of room for improvement when it comes to cost-efficiency. Dennis Lenkering, Managing Director of Lenkering Montage- und Zerspanungstechnik GmbH in Steinfeld, in the German region of Lower Saxony, was determined to do something about this. He worked with the in-house design team to devise a whole host of different approaches and one proved a winner. The modular MP EcoLine® series was released just six months later.

Flexible custom assembly work bench

The series has a standardised, adaptive basic system that enables several products to be made semi-automatically and checked on a single assembly work bench. Numerous interfaces can be added as required by the customer. Thanks to modular plug connections, the setup time when adapting the work bench is less than five minutes. What’s more, a special coding system ensures that the relevant adaptations no longer need to be introduced through specific program selection. They are initiated entirely automatically, which also makes operating errors far less frequent.

A trolley is used for transport purposes. It is easy to adapt the integrated height-adjustable table to the level of the trolley because the height can be saved and called up at the touch of a button. The transport trolley can then be pushed against the assembly work bench. Its castors are locked in position and the assembly work bench’s transport securing device is released, which means the add-on can now be slid directly into the MP EcoLine®. In just a few simple steps it is secured and connected to the assembly work bench, including a compressed air connection.

Versatile and ergonomic assembly work benches

Subsequent operation is both convenient and ergonomic, above all thanks to the special item solutions installed. Line 8 from the MB Building Kit System with its partially closed or fully open grooves and the item Work Bench System are used to build the assembly work bench. Lenkering has belonged to the item pluspartner network since 2016. It particularly appreciates the compatibility of our solutions across all Lines and the close collaboration we offer.

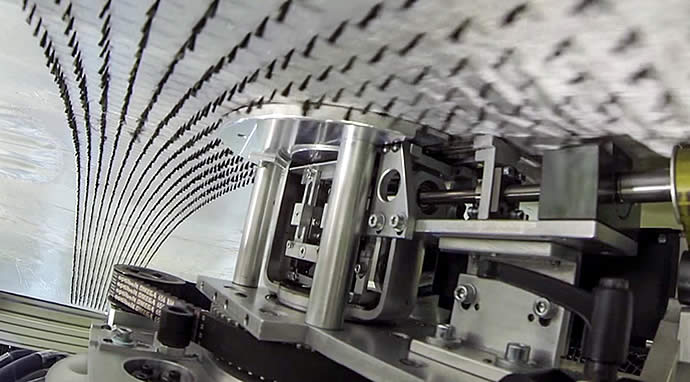

Workflows are displayed graphically using the touchscreen panel and the control system behind it. Furthermore, instructions and other messages are output unencrypted. An assembly work bench from the MP EcoLine® series can also be augmented with industrial PCs (IPCs) and communication interfaces. This makes it easy for data to undergo further processing and, for example, be forwarded to the in-house intranet, so the assembly work bench is also suitable for Industry 4.0. Other possible modules that can be integrated include electric gears and axes, camera systems and equipment for leak and flow tests.

Are you interested in fascinating reports and innovations from the world of specialist mechanical engineering? Then we have the perfect solution for you – simply subscribe to the item blog by completing the box at the top right!