Linear technology is subject to high demands, so a great deal of know-how is required when selecting and designing such solutions.

Key questions include the following: Which drive technology is most appropriate for each transport task? What level of repeatability is required? And which motion profile is most suitable? This is where item MotionDesigner® comes in. Besides ensuring requirements are transparent, it also makes reaching decisions and defining the relevant parameters easier. The online software provides users with targeted support when they are selecting and designing item linear technology. It sifts through thousands of possibilities to calculate the perfect combination of Linear Unit, Motor and Controller for the specific task. In addition to saving a great deal of time, users of the free item MotionDesigner® thus also obtain vital knowledge about linear technology. A didactic approach based on a logical progression of steps not only makes the software easier to use, but also provides clear answers to fundamental questions, making the software an ideal introduction to the world of linear technology and a helpful training aid. The tool is complemented by the “Basics of linear technology” online training module in the item Academy. The only requirement to access this module is a free item user account.

Automation Ideas in Motion

1,000 combination options, one recommendation – the item MotionDesigner simplifies the selection and design of the right linear solution. Based on your specifications, the configuration software finds the ideal linear unit for your application in a matter of seconds. Start now!

Specific guidance on designing linear technology, plus useful know-how

When selecting and designing linear units, all the necessary technical details and the circumstances of the intended application need to be queried and analyzed. “Parameters that go much further than straightforward technical details and have been determined in comprehensive calculations and measurements are also built in. The software taps into this specialist expertise, so it can suggest the perfect solution in the shortest space of time,” explains Johannes Sodermanns, product manager for machine automation at item. Alongside this, item MotionDesigner® covers the basics of linear and drive technology. In this way, users discover which components in which dimensions are relevant for the automation solution, and which details need to be defined. The software sets the focal points and breaks down the configuration process into separate sections. Users formulate their transport task in a simple and intuitive dialogue with the intelligent software. They are guided step by step through the various sequential sections.

The same strategy is used for the entire process – from selecting the Linear Unit through to compiling the project documentation. This structured approach creates clarity throughout, which provides a basis for users to take a close look at various focal points when designing a Linear Unit. Linear technology know-how is imparted along the way, almost as a side effect. Which drive type, motorization, control system, gearbox and drive sets might be worth considering? Users obtain detailed answers to such questions, which are essential to find the appropriate solution for the relevant automation task. Additional information and definitions can also be viewed at numerous points when parameters need to be adjusted or technical data needs to be recorded. Repeatability and duty cycle are defined, for example, and the functions and tasks of encoder systems are explained. General information and tips like these give users a more in-depth understanding of linear technology.

Step by step to the ideal Linear Unit

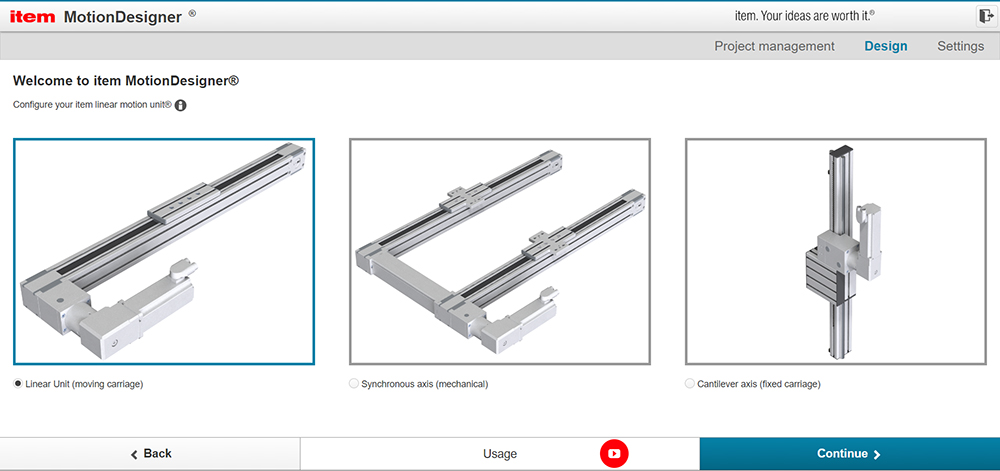

item MotionDesigner® guides users systematically through the configuration process. The first step is to decide between product selection and detailed configuration. If opting for product selection, users just need to enter a few details before choosing the Motor, Gearbox and Controller they want from a selection of compatible components. With the detailed configuration option, on the other hand, the online tool guides users through all the configuration steps, asking specifically about their application’s general circumstances, mounting arrangement, load scenario and carriage movement. On this basis, the software recommends the appropriate solution – an ideal combination of Linear Unit, drive and Controller. So how does the step-by-step process work? Users who select the detailed configuration option can choose between an individual Linear Unit, a cantilever axis and a synchronous axis. In the next step, they specify the relevant general circumstances, such as the repeatability and drive technology that are required and the electrical power supply at the place of use. Details regarding the encoder system, the environmental conditions and the technical parameters of service life and duty cycle are also needed.

The next step is to determine the mounting arrangement and carriage alignment, after which the motion profile is defined. Based on the motion and load profiles entered, along with precise calculations, item MotionDesigner® then suggests an item Linear Unit. The next task is to define the assembly position. This is where users determine the position of the drive components and the arrangement of the Gearbox and Motor, also indicating whether the Controller is to be supplied parameterized. At the final stage, users have the option of specifying the basic components they want and can also select additional Controller accessories and any Cables required. If necessary, item MotionDesigner® compiles detailed project documentation. It can also supply CAD data and generate a configuration file that is subsequently transferred to the item MotionSoft® commissioning software. The desired solution can be ordered from the team of item Experts.

Users selecting the detailed configuration option can choose between an individual Linear Unit, a cantilever axis and a synchronous axis.

Valuable linear technology knowledge and help with data entry

The methodical approach used during the configuration process and the numerous tips and help functions in the tool are especially practical. For example, users are given valuable pointers on analyzing data and facts appropriately. Informative illustrations also provide helpful linear technology knowledge. When specific values need to be entered, the software automatically limits the range for possible entries to allow only realistic values. For example, the stroke length must be between 0 and, 5820 mm. This specifically prevents incorrect entries, design flaws and unnecessarily complex tasks. If individual parameters are changed, the software automatically adapts to the new scenario in a matter of seconds.

“Performing calculations after a value has changed takes much longer with manual configuration than it does in item MotionDesigner®. Users tend to avoid making changes in such cases, whereas our software ensures they can easily and quickly experiment, try things out and compare different approaches,” explains Sodermanns. Example applications and learning content that have been created in the software can be saved and reopened time after time, for instance. The “Basics of linear technology” module in the item Academy is recommended for any user who wishes to find out more about how linear technology works, and about the various types of linear guide and drive technology. Thanks to its interactive design, this online training module with numerous 3D animations explains the theory of linear technology very clearly.

Having to position components with a click or tap helps the technical structure stick better in the user’s mind. In this example, the assembly of a timing-belt drive is explained.

Teaching staff and students benefit from linear technology software

item MotionDesigner® is a browser application in the cloud, so the only requirement to use it is a device with internet access. No updates or downloads are necessary – this smart selection and design tool is always up to date and ready to use. It can also easily be incorporated into video conferences or webinars. Participants can then follow all the steps in real time, wherever they happen to be. “item MotionDesigner® isn’t just a software solution that considerably simplifies and speeds up the configuration of linear systems. It’s also an online tool that is ideal for training purposes,” emphasises Sodermanns. From training workshops and vocational schools to company training facilities, the tool is perfect for teaching the basics of linear technology.

Teaching plans can be based around the logical structure of item MotionDesigner® – from the definition of a Linear Unit, the general circumstances of an application, the basics of linear technology and a description of individual components all the way through to accessories and final documentation in line with machinery directives. The direct practical correlation serves to extend and consolidate teaching content. Thanks to this tool, if teaching staff are looking to explain subject matter such as drive and guidance technologies or the influences of static and dynamic aspects, they don’t need any additional materials to plan their lessons. Students benefit, too, as they can use the tool at home or in other locations to gain more in-depth knowledge at any time.

Interested in learning more about linear technology? Simply subscribe to the item blog by completing the box at the top right! Don’t forget to enroll in the item Academy today to continue your education in linear.