Swiss students spearhead innovative space research

A group of students from Switzerland has completed a highly ambitious project – building and launching a hybrid rocket.

Swiss universities are known for often producing impressive and forward-thinking practical projects. item is eager to support the next generation of pioneers and innovators. In fact, teams of Swiss students have already successfully used our components to develop an earthquake robot, a weeding robot and a construction site robot fit for outer space. A new, fascinating project in the field of space exploration is currently being carried out by ARIS, the student association for space travel in the German-speaking part of Switzerland. This association was founded by 15 students from ETH Zurich and now has a total of 150 students from various universities and study programms, all championing the ARIS motto: “Space to grow”. “We don’t look at what people are already able to do, but what they are learning and how they want to expand their minds,” explains Xeno Meienberg, ARIS project manager and master’s student in mechanical engineering at ETH Zurich. The aim of the new project is to develop a hybrid rocket using profiles from the item MB Building Kit System for take-off and tracking solutions.

Space research in Switzerland – leaving gravity behind with a hybrid rocket

The hybrid rocket is being developed by 50 students as part of the PICCARD space research project. It is named after the Swiss scientist Auguste Piccard, who in 1931 became the first person to enter the stratosphere. The aim is to use the rocket, which is six metres long and weighs over 100 kilograms, to launch a payload approximately 9.6 kilometres into space for the purposes of conducting a scientific experiment there. “Our payload is an acoustic device that can make a small object float using sound waves,” explains Meienberg. “We want to find out whether this works under the high g-forces of the rocket launch – and later in microgravity as soon as the rocket reaches the desired altitude.” The latter makes it possible to conduct the experiment under weightless conditions.

Mechanical engineers, electrical engineers, physicists, mathematicians and business students are all involved in the PICCARD project. “We have a highly interdisciplinary team, where students of a certain subject learn to work together with their colleagues from other disciplines,” says Meienberg. Running alongside this endeavour is the DAEDALUS project, in which six students are focussing exclusively on developing the rocket propulsion system. A hybrid rocket uses several phases of fuels and oxidants instead of solid propellant. “We use a simple mixture of sugar (sorbitol), paraffin and aluminium as combustion fuel,” explains the project manager. “Oxygen is also required – this is where nitrous oxide comes in.” Since combining these substances could result in a dangerous mixture, the nitrous oxide is stored in a pressurised tank separate from the fuel. This makes the PICCARD rocket extremely safe.

We have a highly interdisciplinary team, where students of a certain subject learn to work together with their colleagues from other disciplines.

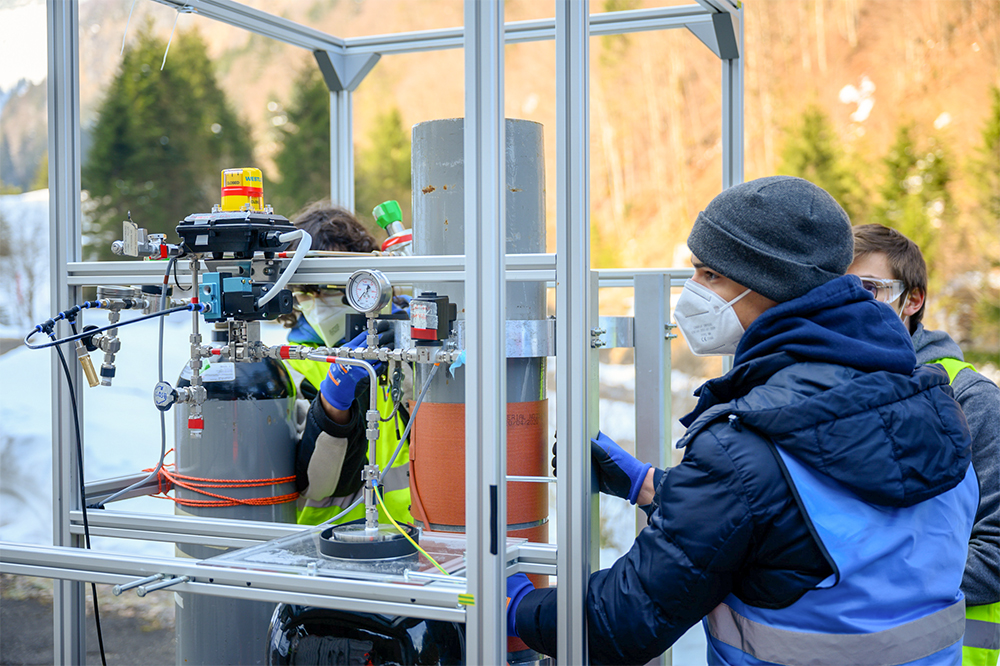

The PICCARD team has developed a special structure for filling the rocket.

Frame for the remote filling station and rocket tracker made using profile technology

The hybrid rocket must be filled with nitrous oxide for take-off. To protect everyone involved, the students developed a special structure that makes it possible for the rocket to be filled from a distance. “This remote filling station is placed next to the rocket before take-off. We can then control it electronically from a distance,” says Meienberg. This in-house development makes a major contribution to the safety of the rocket launch. The frame of this structure, which is two metres high and approximately 1.5 metres wide, is made entirely of item profile technology. “This is the first time we’ve worked with item. We became aware of the MB Building Kit System through the overwhelmingly positive reviews we heard about it from other projects at ETH Zurich. Collaborating with item was a great experience for us, too,” says Meienberg. The item Engineeringtool was used for the design, and the team’s engineers were impressed by its intuitive interface and intelligent functions.

A rocket tracker is positioned 500 meters away from the hybrid rocket before take-off so it can be monitored. “There is a tracking device on board the rocket that provides information about its current location,” says Meienberg. The tracker, which is 1.9 metres in height, receives the signal from this device. item profiles were also used to build the frame for the tracker box, measuring 30 × 30 × 40 cm. Using a second tracker also makes it possible to infer how the rocket behaves in three-dimensional space. The team was particularly impressed by the material properties of the robust profiles: “They are very stable. We launch rockets from special locations – such as the desert or the Swiss mountains, where this level of stability is absolutely essential,” explains Meienberg. The modular design plays a crucial role, too: “When the project is finished, we can simply reuse the profiles,” he adds. “You can build on these structures again and again, add to them or restructure them. This is very practical for our particular applications – and highly sustainable.”

The item profiles are very stable. We launch rockets from special locations, like the desert or the Swiss mountains, where this level of stability is absolutely essential.

Rocket trackers make it possible to accurately monitor the hybrid rocket.

Healthy competition among up-and-coming space researchers

In the field of space research, there is a lively international scene of young talent. Numerous competitions give students the opportunity to see how they measure up against other teams. The PICCARD team showcased its hybrid rocket for the Spaceport America Cup in June. Due to the coronavirus pandemic, the US competition was held as an exclusively virtual event. Finally, the team plans to participate in the second edition of the European Rocketry Challenge (EuRoc) in Portugal, which is scheduled for October 2021. Moving forward, the researchers intend to continue working with item in the long term – and not just for rocket projects. “Starting next autumn, for example, we will be working on a solar panel installation device. This will be a kind of robot that can install solar panels on another planet completely autonomously,” says Meienberg.

Keen to stay up to date on the various ways that item products are being put to use? We have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.