For years, “the factory of the future” sounded like a distant vision – highly automated, data-driven, and powered by intelligent systems. Today, that future is already unfolding across North America. Manufacturers of all sizes are actively investing in smart manufacturing technologies to improve agility, productivity, and resilience in an increasingly competitive global market.

According to Deloitte’s 2025 Smart Manufacturing and Operations Survey, 92% of U.S. manufacturing leaders believe smart manufacturing will be the primary driver of competitiveness over the next three years, with companies already seeing measurable gains in output, productivity, and capacity utilization. As digital tools evolve, so must the physical environments that support them—making flexible, modular infrastructure a critical foundation of the modern factory.

Smart Manufacturing in North America: Concept to Reality

Smart manufacturing – often associated with Industry 4.0 – integrates advanced technologies such as industrial IoT (IIoT), real-time data analytics, automation, artificial intelligence (AI), and digital twins into production environments. Adoption across the United States is accelerating rapidly.

Market research estimates the U.S. smart manufacturing market will grow from approximately $74 billion in 2024 to more than $160 billion by 2030, driven by increased automation, connected equipment, and advanced analytics. These investments are no longer limited to large OEMs; small and mid-sized manufacturers are also adopting smart technologies to remain competitive, supported by federal and state-level initiatives through organizations like NIST and the Manufacturing Extension Partnership (MEP) network.

Yet while software and automation systems often dominate discussions, the physical factory layout remains a decisive factor in whether smart manufacturing strategies succeed or stall.

Why physical infrastructure matters in a digital factory

Smart manufacturing environments demand far more than traditional, fixed production layouts. Connected machines, sensors, robots, and data collection systems require infrastructure that can evolve alongside technology.

Deloitte research shows that many manufacturers struggle not with technology selection, but with scaling implementation across existing facilities. One of the biggest barriers is inflexible factory infrastructure: steel-welded frames, permanent guarding, and rigid workstations that are costly and time-consuming to modify.

This is where modular factory systems play a vital role. Flexible aluminum framing, reconfigurable workstations, and adaptable machine enclosures allow manufacturers to redesign layouts quickly as processes, products, and automation strategies change.

Building flexibility into the factory of the future

Organizations like the National Institute of Standards and Technology (NIST) emphasize that interoperability, adaptability, and scalability are essential characteristics of smart manufacturing environments. Physical systems must support rapid change – whether that means adding sensors, integrating collaborative robots, or adjusting workflows for new product lines.

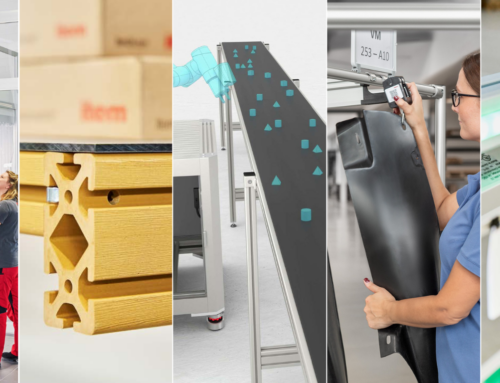

The item America modular building kit system aligns directly with these needs by enabling:

- Rapid reconfiguration of production lines without welding or fabrication delays

- Scalable automation platforms for robotics, conveyors, and machine bases

- Integrated mounting solutions for sensors, vision systems, and cabling

- Custom workstations and ergonomic solutions that support digital workflows

Instead of designing factory layouts as permanent structures, manufacturers can treat them as adaptable frameworks: ready to evolve as new technologies are introduced.

Smart manufacturing is driving workforce-centered design

Despite increased automation, people remain central to smart manufacturing success. Deloitte reports that workforce challenges including talent shortages and skills gaps are among the top barriers to smart manufacturing adoption in the U.S.

As a result, factories are being designed not only for machines, but also for human operators who interact with digital systems daily. Ergonomic workstations, clear visual management systems, and safe human-machine collaboration zones are increasingly important.

Modular workstation systems from item America support these goals by allowing manufacturers to:

- Adjust workstation heights and layouts for ergonomic optimization

- Create standardized yet customizable work cells

- Integrate monitors, scanners, and digital interfaces seamlessly

- Improve safety through adaptable guarding and enclosures

These improvements help attract and retain skilled workers while enabling faster training and smoother adoption of smart technologies.

Supporting data-driven, sustainable manufacturing

Sustainability and energy efficiency are also major drivers of smart manufacturing investments in North America. Studies show manufacturers are increasingly using real-time monitoring and smart energy management systems to reduce waste and improve resource efficiency.

Modular factory infrastructure supports sustainability goals by:

- Reducing material waste through reuse and reconfiguration

- Extending system lifecycles compared to welded steel structures

- Supporting lean manufacturing principles and continuous improvement

As manufacturers pursue smarter, greener operations, infrastructure that can be repurposed rather than replaced becomes a strategic advantage.

The factory of the future is modular by design

Smart manufacturing is no longer an abstract concept—it is actively reshaping factories across the United States and North America today. While digital tools, automation, and analytics are essential, they rely on adaptable physical systems to deliver real-world value.

By enabling flexible layouts, rapid changeovers, and scalable automation, item America’s modular aluminum framing and factory solutions provide the physical backbone needed for smart manufacturing environments to thrive. As technology continues to evolve, manufacturers that invest in adaptable infrastructure will be best positioned to innovate, compete, and grow.

The factory of the future isn’t coming, it’s already here. And it’s built for change.