A key benefit of lean production is the avoidance of waste (Muda). In this blog post, we explain how the item Suspended Conveyor System helps minimize Muda thanks to its innovative design and functionality – a genuine asset for every supply chain, where efficiency is a must.

Lean logistics or lean management has been a familiar concept in modern intralogistics for a long time now. Designing efficient processes, avoiding waste and optimizing material flows are all part of the basic philosophy of the lean concept. But, in practical terms, how can this approach be applied to in-house logistics? As the Suspended Conveyor System from item shows, lean principles are also very much relevant when deciding how to move things from A to B – and they can significantly improve processes, too.

Supplying materials even more efficiently

Supplying materials even more efficiently

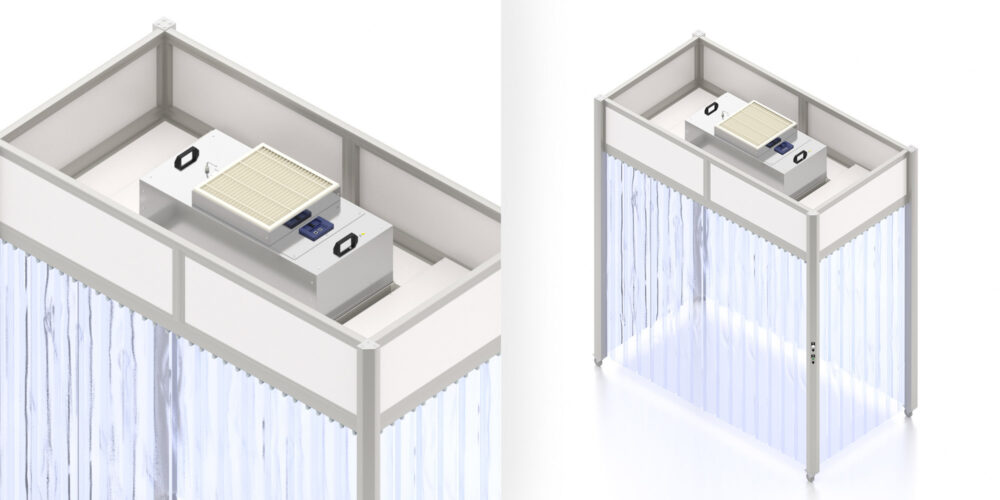

Transport large automotive parts, textiles, or cable harnesses by suspended them – the item Suspended Conveyor System offers the perfect solution for your internal material handling operations.

Lean management and the seven Muda in intralogistics

Lean management is based on a simple but effective principle – reducing waste to boost efficiency. Especially when it comes to intralogistics – moving and supplying goods and materials internally – lean processes and methods can be key to success and efficiency. This is where the “7 Muda” come into play – seven types of waste that can occur in any production process. The aim of lean management is to minimize these.

The 7 Muda at a glance:

- Transport – Unnecessary transportation of materials or products

- Inventory – Superfluous warehousing that ties up capital and often requires more space and management than are actually necessary.

- Waiting – Idle times caused by materials not being available when they are needed or machinery being at a standstill.

- Overproduction – Producing larger quantities than are actually needed at the time often results in more warehousing.

- Motion – Superfluous movements, both of machinery and staff, use up time and energy and lead to higher rates of wear or injuries.

- Overengineering – Set-up processes that are too frequent and workflows that are too complex take up more time and use up extra resources.

- Defects: Faults and defects in products result in rejects or make reworking necessary

Each of these types of waste leads to unnecessary costs and delays in the production process. Methods to eliminate these Muda can be particularly effective in intralogistics, which often involves moving and storing large quantities of materials. By using the right system – one that is designed to prevent waste – internal flows of materials can be made more efficient. The best example of this is our Suspended Conveyor System.

The Suspended Conveyor System from item – bringing lean to intralogistics

The Suspended Conveyor System combines a space-saving design with an efficient transport concept that harnesses the force of gravity. Besides saving energy, this also reduces the need for complex transport containers and for return systems for empty containers. The Suspended Conveyor System is particularly suitable for components that are sensitive or irregular in shape. This space-saving solution is especially gentle on the materials being transported – making it a real asset for any modern supply chain.

The item Suspended Conveyor System offers a number of key advantages over conventional small load carriers (SLCs). The system’s Carriages are smaller and lighter than conventional SLCs. Once unloaded, the Carriages can be collected and returned in compact batches, saving not only space, but time and energy, too. The simple design also makes the system robust and adaptable.

Sensitive components in particular – such as cable harnesses – can be transported with more care in this system. Due to their shape, components of this kind often become entangled or damaged when they are transported in standard containers. With this system, though, they are freely suspended and reach their destination safe and sound. The number of rejects is therefore reduced, and the material flow remains efficient and flawless.

The new Suspended Conveyor System not only helps ensure efficient intralogistics thanks to its lean concept, but also impresses with its clear design. This is why the system won the iF DESIGN AWARD 2024.

The Suspended Conveyor System in the context of the seven Muda – a high-precision approach to reducing waste

Our Suspended Conveyor System helps you avoid typical types of waste identified by lean management:

1: Transport – unnecessary transportation: The Suspended Conveyor System minimizes unnecessary transport operations and processes by collecting together and/or returning empty Carriages in compact batches. The additional work involved in returning empty containers individually – as is often necessary in the case of conventional SLCs – is therefore avoided. The compact return solution reduces the space and resources required, resulting in a leaner, more efficient return transport system in the production environment.

2: Inventory – superfluous warehousing: Using one standardized design of Carriage for different components reduces the need for a variety of empty containers. Instead of needing separate containers for every component, the same Carriages can be used with different holders. This greatly reduces the amount of storage space required and cuts storage costs, because there are fewer different types of container to manage.

3: Overengineering – overly complex manufacturing process: Thanks to the simple design of the Suspended Conveyor System, there are no unnecessarily complicated fixtures or container inserts. This method of transporting parts is much simpler, so no extra processing steps or complex components are needed. The minimalist design meets all the requirements, but without there being any need to invest resources in unnecessary processing, which keeps the production process lean and low cost.

4: Defects – faults and rework: Sensitive components such as cables, cable harnesses and roof liners are hung up and transported more gently. There is therefore less damage than with conventional transport systems – and less chance of cable breakages caused by attempts to untangle materials. This reduces the reject rate and safeguards the quality of the materials.

By specifically reducing Muda in this way, the item Suspended Conveyor System plays an important role when it comes to implementing lean production and offers companies and their suppliers a solution for making their intralogistics more efficient and more resource-friendly. With the help of lean processes and innovative technologies, companies can not only lower their costs, but also optimize material flows and safeguard the quality of their products for the long term.

The bottom line – efficient intralogistics with the item Suspended Conveyor System

The Suspended Conveyor System from item shows how lean principles can be put into practice in intralogistics. By specifically reducing types of waste such as unnecessary transport, superfluous warehousing, overengineering and material defects, the system helps companies put leaner, more resource-friendly processes in place.

At the very time when efficiency and sustainability are becoming more and more important, the Suspended Conveyor System offers a flexible, cost-effective alternative to conventional SLC solutions. Besides helping save space and energy, this system also boosts quality and reliability in the internal flow of materials. The Suspended Conveyor System is a genuine asset for all companies that want to make their intralogistics leaner and fit for the future.

Do you want to keep up to date on the various ways that item products are being put to use? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.