Cleanroom tents – a highly flexible solution for cleanrooms

A cleanroom tent offers excellent flexibility when it comes to clean production, and the innovative item strip curtain takes this to the next level. You can assemble the curtain, attach the Strip Holder, or make adjustments in just a few simple steps.

A total floor area of 3.3 million square meters in Germany, Austria and Switzerland is an impressive figure that illustrates the success of cleanroom technology. What’s more, the cleanroom market is growing all the time. In Germany, the annual growth rate is around 10 percent. Previously, this success was mainly down to the pharmaceutical, chemical and microelectronics sectors. Now, though, cleanroom production is becoming standard practice in ever more industries. For instance, car manufacturers are increasingly insisting that their suppliers set up cleanrooms. It’s a similar story in the mechanical engineering sector in Germany and Switzerland. Especially in Germany, project funding is leading to the growth of semi-conductor production. In addition to this, many innovative technologies developed by start-ups involve working in cleanrooms. Are you looking for an extremely flexible and cost-effective cleanroom solution? Discover the benefits of a cleanroom tent right here! As with other cleanroom applications, the item Building Kit System has everything you need.

System solutions for cleanrooms

Use the modular design principle to create dependable cleanroom solutions! Whether you need a cleanroom tent, a work bench with laminar flow box or a walk-in cleanroom cabin, item will help you implement solutions in exactly the dimensions required.

What is a cleanroom tent?

A cleanroom tent is a flexible, space-saving and cost-effective cleanroom solution. A frame serves as a base to which a ceiling construction is connected. This accommodates one or more Filter Fan Units (FFUs) as well as lighting. Overlapping strip curtains are used as wall elements. In this way, the tent protects the working area inside from external contaminants. The strip curtains ensure a high level of flexibility on all four sides, making it easy for people to enter and exit the tent. Equipment such as a cleanroom-compatible workbench can be brought in, too. The tent is also sometimes referred to as a “softwall cleanroom”. Unlike hardwall solutions such as cleanroom cabins, cleanroom tents do not have rigid walls. Dispensing with walls and doors makes a cleanroom tent more cost-effective than a hardwall solution. Further advantages include easy cleaning and straightforward maintenance, while attaching castors means the tent also benefits from practical mobility.

However, a cleanroom tent is not a direct alternative to a closed cleanroom cabin. It can’t be used for high-purity processes. During such processes, a turbulent air flow mixes newly added and existing air to create clean air. Cleanroom tents with strip curtains normally correspond to high DIN EN ISO 14644-1 cleanroom classes (> ISO 6). Remember, the higher the cleanroom class number, the more particles are permitted in the ambient air. A cleanroom tent is ideal for carrying out simple assembly work, gluing operations and many other tasks under clean conditions. Cleanroom tents and cleanroom cabins therefore complement each other. Everything depends on the specific objective of your particular project.

Online training on cleanroom technology and cleanroom classes

Would you like to find out more about cleanrooms? The online training units “Introduction to cleanroom technology” and “Cleanroom technology regulations, focusing on ISO 14644” are available for free in the item Academy.

Using item components to create mobile or stationary cleanroom tents

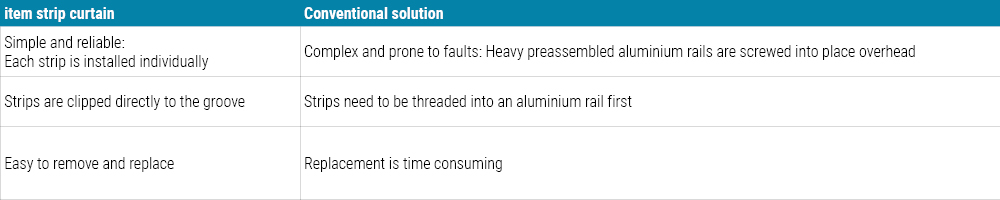

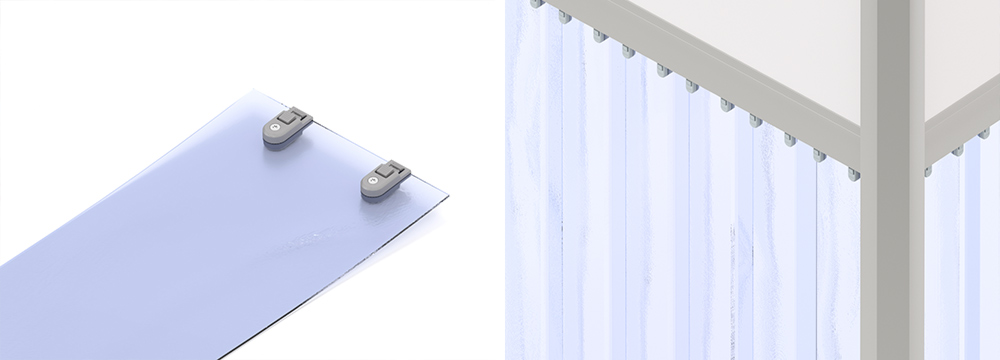

The item Building Kit System makes it easy for you to create cleanroom tents, benefiting from the advantages of our specially developed strip curtains. Each strip installation consists of two Strip Holders and one PVC strip. The PVC strips are up to 2 mm thick and are available as cut-offs or as a 50-meter roll that can be cut to size as required. Each strip is inserted without having to be notched or cut away and, once the Strip Holder has been closed, the strip is secured in place with a screw. To create a strip curtain, you simply need to clip the Strip Holder into a Line 8 groove. This is where the end-to-end compatibility of the item Building Kit System comes into its own. The holder can be replaced quickly at any time. Our solution has none of the problems typically associated with conventional strip curtains:

Line XMS aluminum profiles can be used for the cleanroom tent’s frame. These profiles have integrated cable conduits and smooth surfaces that are easy to clean. Such properties make them the perfect starting point for all kinds of cleanroom solutions. Filter Fan Unit 1200×600 is integrated into the ceiling. FFU StarterKit 230V ensures the FFU is easy to commission and operate. You can control the FFU directly using the operating unit that is included in the scope of delivery. The plug-and-play solution can be fitted onto a profile or panel element. In the case of a cleanroom tent, it is attached to a profile. Thanks to the integrated cable conduit, the cable runs through a profile from the operating unit to the FFU.

In the ceiling, Plastic Pro panels are fitted all the way round. Like all our cleanroom components, these are easy to clean. Large ceiling lights are located to the right and left of the FFU. You should ensure you leave a space of around 10 cm between the strips and the ground. Clean air will then flow through the process space in a controlled manner, ultimately also exiting the cleanroom tent through this opening. Depending on the requirements (mobile or stationary cleanroom tent), Swivel Castors or Leveling Knuckle Feet are fitted to the bottom of the frame.

The Strip Holders (left) attached to the PVC strip can simply be clipped to a Line 8 groove to create flexible and dependable strip curtains (right).

Effective and transparent separation of areas using strip curtains

Our strip curtains aren’t just suitable for cleanroom tents. They’re also ideal for separating different production areas. The PVC strips keep dust and other contaminants out, while also specifically reducing noise and draughts. It is possible to pass through the strip curtains if this is necessary for the relevant application. Staff and transport trolleys can easily make their way through the transparent partitions. Thanks to rapid assembly and disassembly, you can react flexibly to process changes. A mobile solution with castors increases this flexibility further still.

Highly versatile – strip curtains are also useful for separating different production areas. Amongst other things, they reduce loud noises.

Would you like to keep up-to-date with developments relating to cleanrooms? Simply subscribe to the item blog by completing the box at the top right.