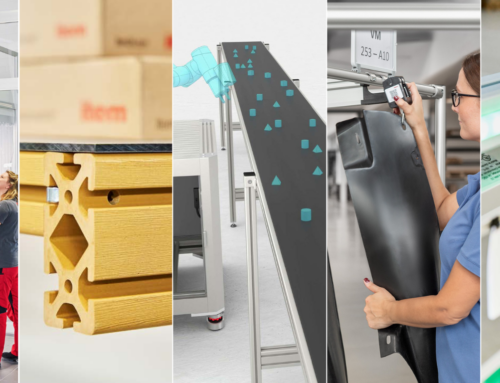

Internal material flows and intralogistics are key factors on the route to optimum production efficiency.

That is why many companies are using automated guided vehicles (AGVs) and continuous conveyors (internal conveyor systems) to introduce as much automation as possible into their intralogistics. Both these solutions require considerable investment and are often overkill for the logistics requirements of many small and medium-sized enterprises (SMEs). However, Götting KG has developed a small, fully automatic AGV for precisely such companies that moves small load carriers (SLCs) between storage racks made of item components and an item Karakuri intermediate store at the production site.

Automating small-scale transport tasks

The Kinetic Automat for Transport Enhancement (KATE) has been specially designed for payloads up to 50 kg. This means no special safety precautions need to be taken when using it. KATE travels directly over the floor surface, and the energy released during a collision is so low that an employee wearing safety footwear would barely feel the impact. All the same, the AGV can of course also be fitted with laser or ultrasound-based obstacle detection systems that bring KATE to a stop before it comes into contact with staff. Additional safety precautions such as these can help to overcome the initial reservations that many employees have with regard to AGVs.

After all, automation is a bonus for all staff, since only very simple and monotonous tasks are taken over that would otherwise use up all the time of one or two members of staff. Instead, these employees can focus on value-adding tasks. The driving/steering module in KATE communicates via WLAN with a control computer and the TransportControl system. TransportControl is operated directly in a web browser, with no plug-ins or additional software needed.

Optimising intralogistics with AGVs

The track guidance system of the AGVs also helps ensure a rapid return on investment for SMEs by using route markers that are stuck to the floor and transponders. As a result, there is no need to take up the floor to lay the guide wires often used by similar systems. All these features convinced a shared customer of item and Götting to replace its ceiling-mounted belt conveyor system with small AGVs.

The aim of this switchover was to significantly reduce handling in production. KATE picks up an SLC from a rack system in the warehouse and automatically conveys it to an intermediate store, so that all employees have to do is load their machine. KATE also automatically picks up empty SLCs from the intermediate store and returns them to the warehouse. As a result, the AGV takes care of all material supply and removal tasks. Thanks to software and sensors, the supply of materials can be controlled automatically, completed at fixed intervals in accordance with plans or even initiated manually by staff at the intermediate store, e.g. using a tablet.

Customised item racks and Karakuri solutions

To ensure full automation can work in practice as it does in theory, companies need rack systems that can be adapted to suit the specific transport task. Götting KG identified a number of critical factors, including the huge selection and rapid availability of item components and the benefits in terms of simplicity and speed that a modular system offers when building bespoke customer solutions. Other important plus points were the high quality of the aluminium profile technology and the long-term stability of the fasteners. Indeed, it is crucial that automated material flows in three-shift operations can be run on a long-term basis without the need for major additional maintenance work.

However, as a specialist primarily in AGVs and the conversion of conventional vehicles for driverless use, Götting KG was reluctant to build the necessary rack systems itself. The customer’s requirements were therefore passed on to the item site in Hannover, where the bespoke solution was planned and engineered. Since they use our modular building kit systems, the rack systems can be perfectly adapted to the shape, length and sizes of customer containers.

Putting AGVs to the test at the Hannover Messe trade fair

In practical terms, the requirements for the resultant AGVs were as follows: Four different components, which are stored in SLCs at the company, are needed at a machine. The pick-up points in the warehouse are programmed into the AGVs. A lifting table and a driven roller conveyor are the only active elements involved.

After collecting the material from the warehouse rack, KATE automatically travels to the machine at the intermediate store with the relevant four compartments. The small automated transport unit selects the correct compartment for the material it is carrying and transfers the material via a passive Karakuri solution, taking back an empty SLC and then returning this empty to the warehouse.

Want regular updates on the latest exciting applications to use our solutions? It couldn’t be easier, simply subscribe to the item blog by completing the box at the top right!