Interoperability holds the key to efficiency in modern-day logistics

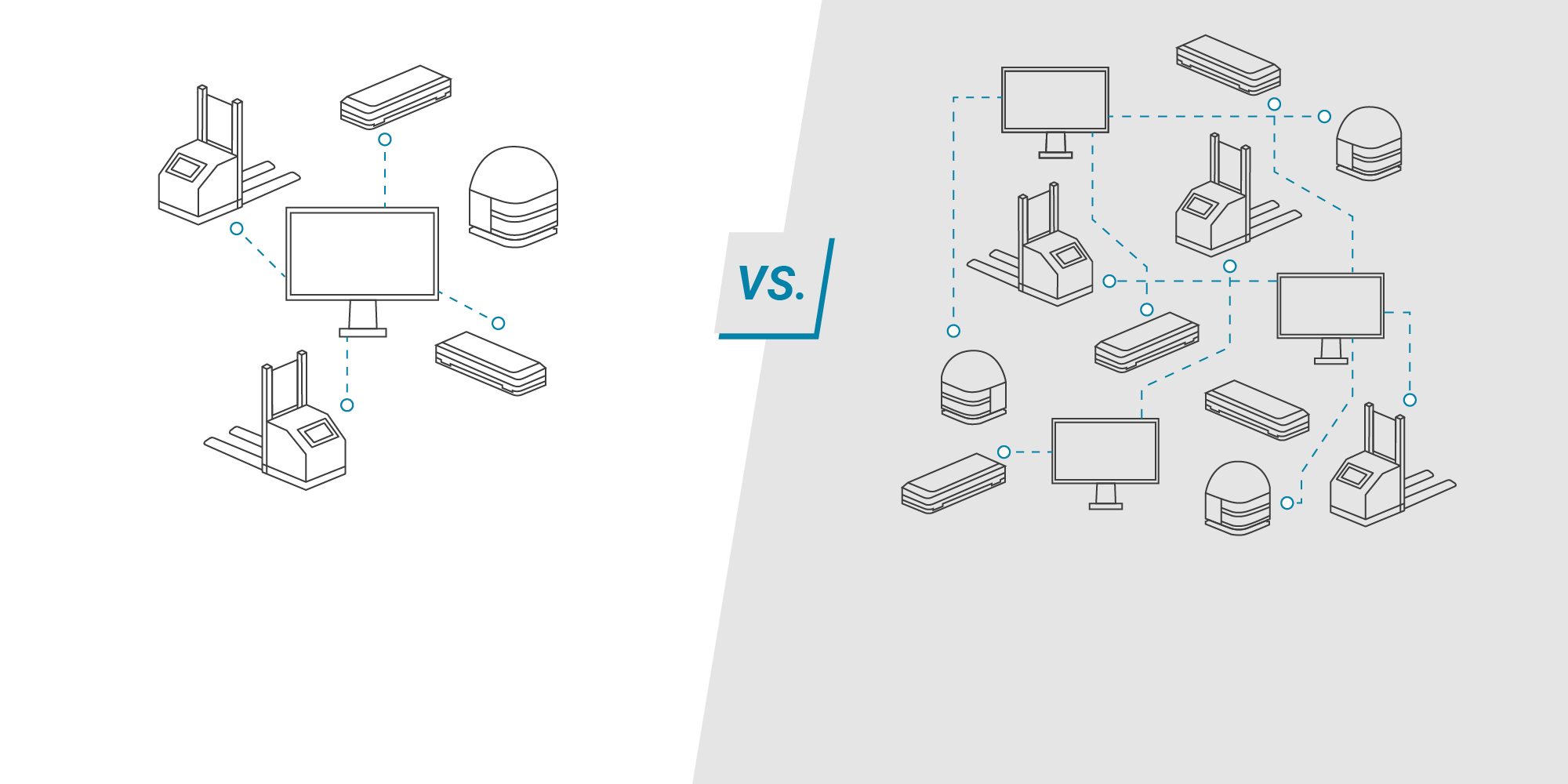

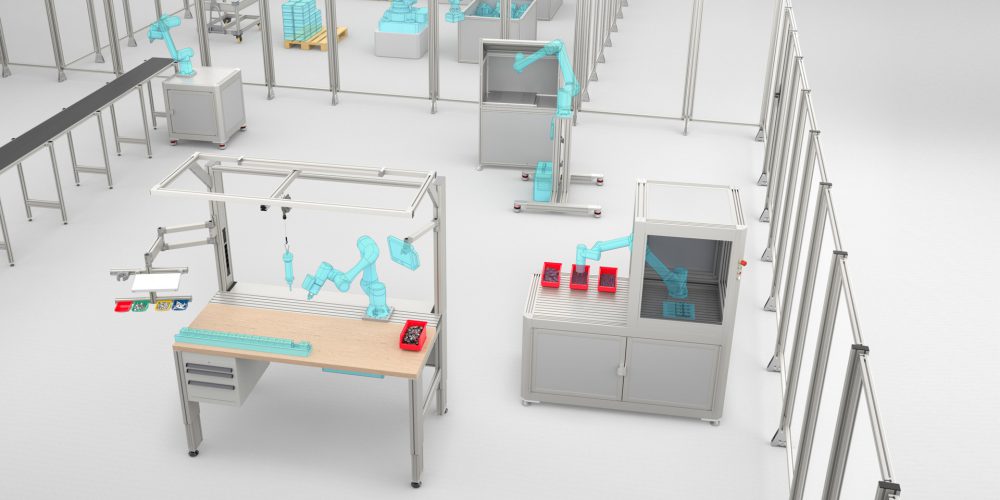

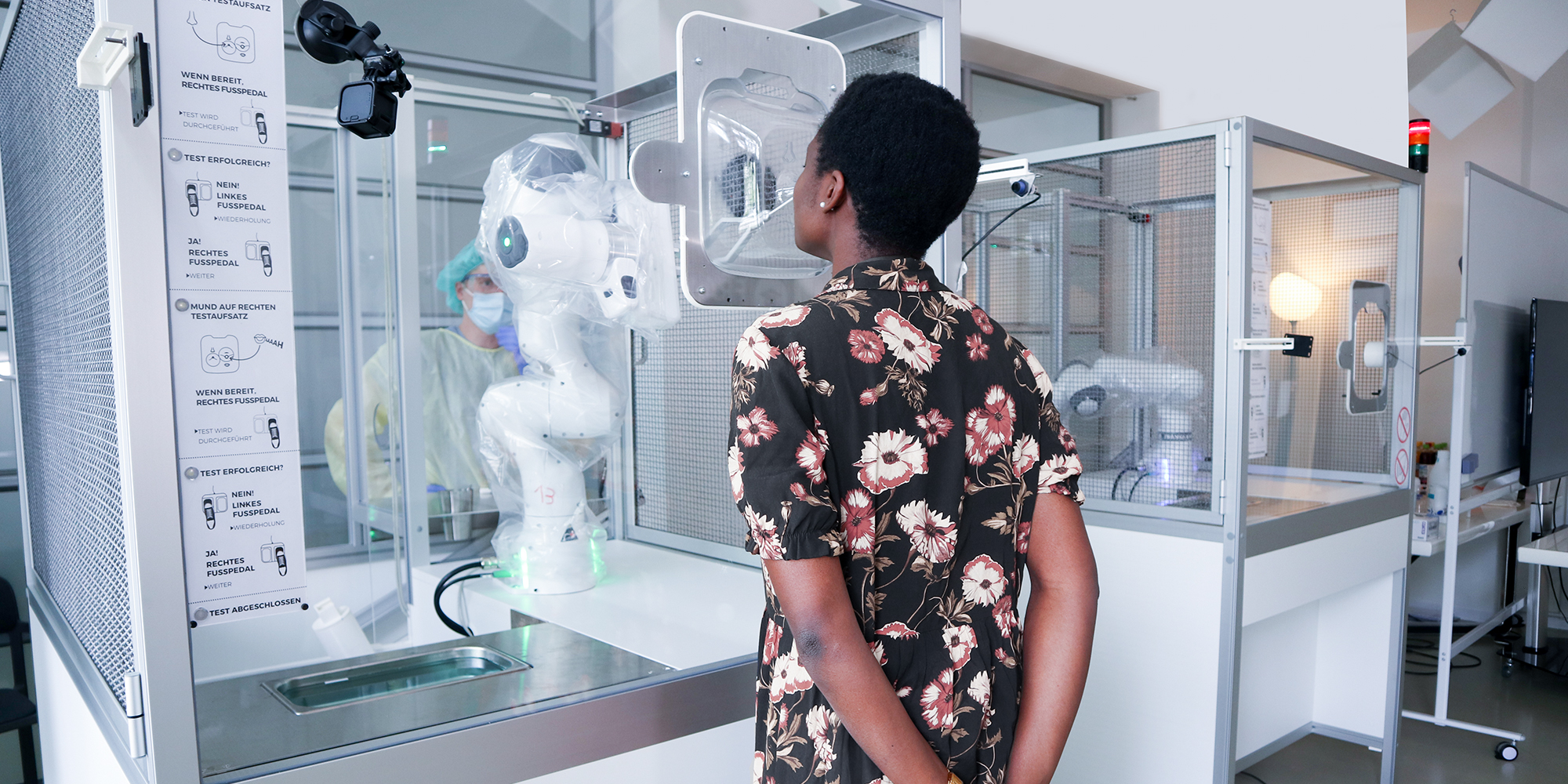

Interoperability enables the mobile robots and systems of different manufacturers to work together seamlessly. Discover how standardizing systems and using platforms improves efficiency and flexibility in logistics operations.