What does the often abstract concept of “going digital” actually mean?

Even though few things these days are being talked about as much as “going digital”, it’s all too easy to lose sight of the basics. Even the terminology can be tricky – are we talking about “digitalisation” or “digitisation”? Is there a difference between the two and, if so, what is it? Digitisation refers to the technical process of converting analogue data into a digital format. By contrast, digitalisation – in a corporate context – refers to the use of digital technologies to improve in-house processes or help develop new products, services or business models. In a wider, societal context, the term “digitalisation” describes the transition that is seeing digital developments pop up in all aspects of society. Other similar terms that highlight this process of change are “digital transformation” and the “digital revolution”.

The many sides to digitalisation

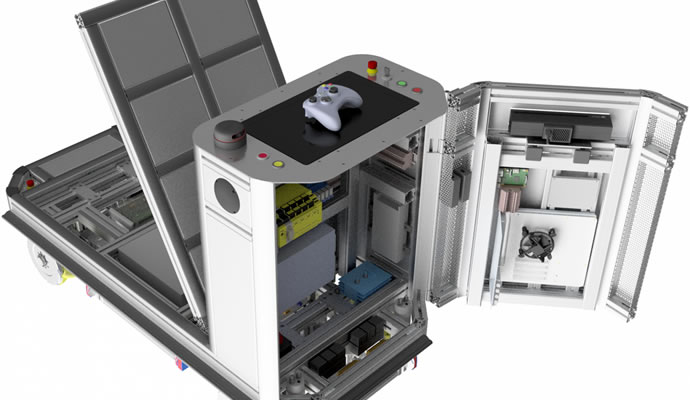

Focussing on “digitalisation”, one of the key advantages it offers is the ability to easily create, access and share content independently. Being able to share information across different locations – as is the case with digital engineering – gives rise to new forms of collaboration. Employees can coordinate and work on projects together with their international colleagues or partners on different continents, for instance. The item Engineeringtool, for example, makes this easily possible by using globally unique project numbers. The digital infrastructure within a single site is also very important, which is shown, among other things, by the lasting increase in productivity when staff can use their operating system account to log into flexible workstations as and when required. This kind of system makes it easier for interdisciplinary teams to come together at a site and extend their collaboration.

But we mustn’t ignore the human side of things when examining digitalisation, as companies will never complete their digital transformation if their staff aren’t keen to go along with it. This is where the interdisciplinary mindset we touched on above is crucial, as new working practices and business models call for a much broader perspective and the ability to absorb and utilise know-how from other disciplines. Given the need to engage in dialogue, digitalisation lends even greater weight to employees’ social skills and intercultural competences. Be it in person or via Skype, with a colleague from another department or an important customer from a far-flung part of the world – being able to adapt to all sorts of situations and expectations is vital.

Explaining digitalisation based on examples from mechanical engineering

As digitalisation advances, numerous new fields of business are opening up in mechanical engineering that tap into tried-and-tested concepts from other sectors. A frequently cited example are subscription models involving fixed-term contracts for machines. This is where the customer rents the machine for only a set period of time instead of buying it outright. The machine itself remains the property of the manufacturer, who can check its performance data at any time via an internet connection. Alternatively – or in addition – the customer can opt for ‘predictive maintenance’. In this system, all it takes is a small deviation in the transmitted performance data and a warning is issued about potential defects.

This makes it easier for service providers to plan on-site servicing, while customers can reduce the risk of downtimes to the bare minimum. All the same, both these business models rely on customer uptake, and security concerns in particular can often prove to be a stumbling block. However, deploying effective solutions to safeguard company data and intellectual property can alleviate customers’ worries. Doing so also favours other noteworthy business models such as special online market places where companies could market their specific engineering know-how. In other words, the opportunities offered by digitalisation may well see engineering data evolve into a commodity in the future.

Are you interested in digitalisation and what the future of mechanical engineering holds?

Then we have something that might just help! Simply subscribe to the item blog by completing the box at the top right!