Green light for your ideas – new LED strip with IO-Link Controller

Scope for maximum configuration options – our new LED strip can not only be shortened as required, it can also be controlled individually via the specially developed IO-Link Controller.

Different-coloured light signals provide clear direction for flows of traffic – and indicator lights in industry play a similar role. While a red light in the road ahead tells you to stop, in a production facility it serves as a warning that a dangerous situation requires attention and action. As you can see, colours are used as visual signals in industrial environments, too. Our new Multi-Segment RGB LED Strip can light up in any desired colour for this purpose. This is thanks to the connection to IO-Link via our specially developed IO-Link Controller, which enables the light functions and colours of the LEDs to be defined individually. At the same time, the strip – which is up to six metres long – can be shortened one LED at a time. This opens up optimum visualisation options for a whole range of applications in intralogistics and industrial production. This solution is part of our new signalling solutions product series launched in 2023.

item solutions for customised signalling

item solutions for customised signalling

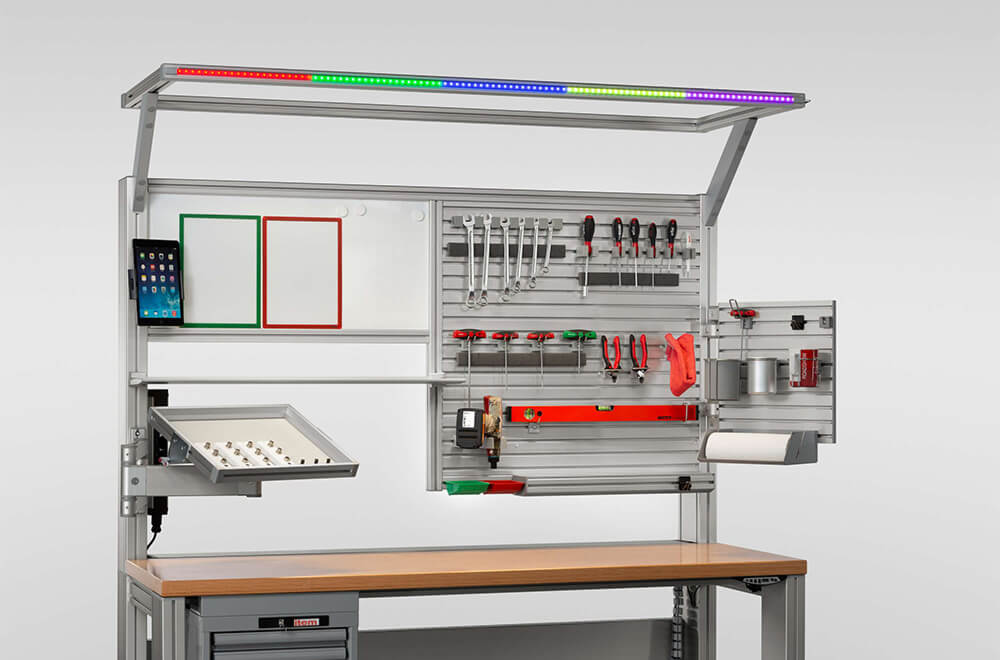

Whether you want to display the operating status of machines and industrial systems or visualise the status of processes at the work bench, our signalling solutions will ensure you can always see what’s going on.

IO-Link – an established industry standard

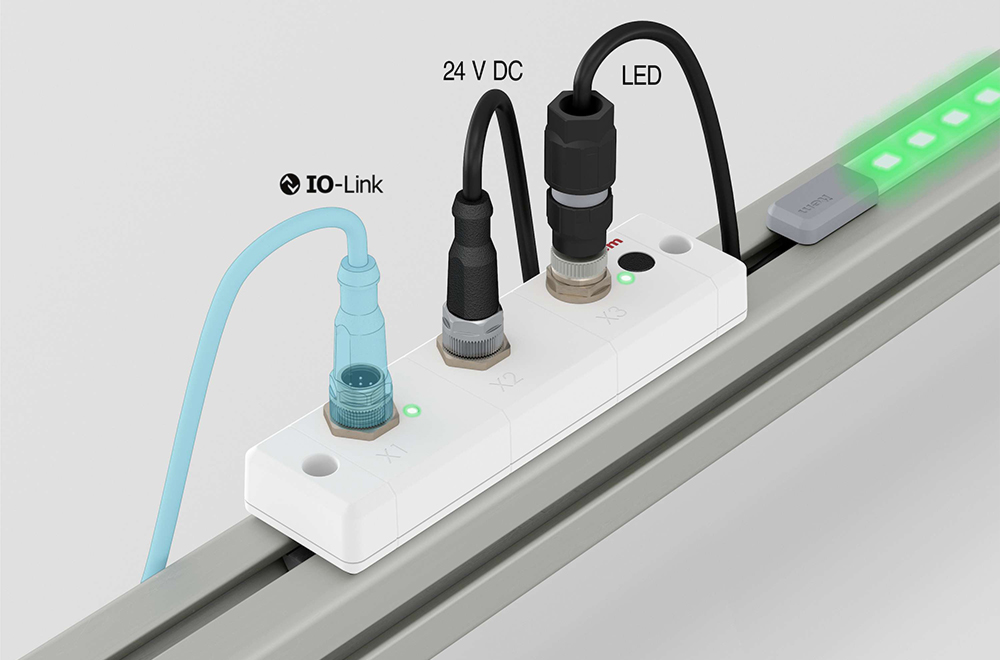

The wide range of options for customising our new LED strip comes from its connection to an IO-Link Controller that communicates with the machine controller via an IO-Link master. Thanks to its expanded diagnostics, simple installation and central parametrisation, IO-Link is becoming an increasingly popular solution for connecting sensors and actuator systems. As a bidirectional point-to-point connection, IO-Link can not only transmit commands to the sensors and actuators it is connected to, but also make periodic status update queries and forward these to the machine controller. In addition, the relevant device sends an error message or warning to the IO-Link master when it is overheating or reaching the end of its maximum operating time, for example. At the same time, the master receives process data from the individual devices at predefined intervals, and can also check the data from equipment on command. A further advantage of IO-Link is the option of storing the parametrisation data of the connected devices on the master. When a new device is installed, this data is easily transferred, significantly shortening the connection time for the sensor or actuator concerned.

Commissioning and setup of our IO-Link Controller can be carried out directly on the controller or via an IO-Link master. It offers four different operating modes: “Countdown”, “Fill level”, “Segment display” and “Highlight”. All enable custom parametrisation via IO-Link.

item develops world first for connecting to IO-Link

We wanted to make use of these major benefits for our new Multi-Segment RGB LED Strip, too. The challenge was creating an interface between the LED strip and the IO-Link master. As Jens-Uwe Gustmann, Product Manager for Smart Products at item, explains, “There was no solution for this scenario on the market at the time. It was therefore up to us to develop one. That’s how the IO-Link Controller from item came to be – it’s a world first that enables standardised communication with tried-and-tested connection technology for sensors and actuators.”

Here’s how it works. The IO-Link Controller is connected to the master, a power supply and the LED strip via three M12 connections. Commissioning and parametrisation can be carried out practically and rapidly directly on the controller or via the master. The result is straightforward, extremely flexible control of the LED strip using IO-Link.

There was no solution for this scenario on the market at the time. It was therefore up to us to develop one.

“Countdown” mode can indicate rising or falling fill levels. Warning and alarm thresholds can be set as required to indicate critical states when levels surpass or fall below these.

Signalling solution based on the tried-and-tested building kit principle

Just like the tried-and-tested Building Kit System of item components, the LED strip offers a huge range of configuration options when combined with the IO-Link Controller. The strip can also be shortened one LED at a time. “Our solution offers a much more flexible alternative to more conventional indicator lights and machine traffic lights. It is particularly well suited to signalling fill levels, process times and process statuses on manufacturing lines and workstations,” explains Gustmann. “Using appropriate sensor technology, it is possible to clearly indicate the operating status of machines and industrial systems, for example, so that employees can see this directly at a glance, even from a distance.” A Casing Profile that can be opened up and, practically, shortened to the length of the LED strip using multi-purpose pliers, provides the necessary protection. The ends of the profile are closed with a Cap that also provides strain relief for the connection cable of the LED strip at the connection end.

Our solution offers a much more flexible alternative to more conventional indicator lights and machine traffic lights. It is particularly well suited to signalling fill levels, process times and process statuses on manufacturing lines and workstations.

The Multi-Segment RGB LED Strip with IO-Link connection is just one of our new range of signalling solutions. For example, we also have 1-Segment RGB Indicator Lights, 3-Segment Indicator Lights and Multi-Segment RGB Lights in our portfolio, and all of these can be parametrised using IO-Link. They can be controlled via trigger inputs or IO-Link as required.

In “Segment display” mode, between one and five sections of the LED strip are controlled with precision. This mode is a substitute for conventional machine traffic lights or stacked lights. Statuses can be highlighted in a striking way using patterns of lights or flashes.