The meaning behind lean production terminology.

Lean production concepts continue to be successful, whether applied directly in industrial processes or in a slightly modified way in lean management. But for those new to the topic, the numerous and by no means self-explanatory terms can easily be confusing. At first, the various abbreviations and/or Japanese technical terms may seem uninviting. If you take a closer look, however, you will discover fascinating and logical ideas for process optimisation. In this blog post, we aim to give a compact overview of the main lean production methods.

The continuous improvement process (CIP)

The continuous improvement process (CIP) is at the heart of all lean production methods and is based on the concept of “Kaizen”, transferring it into an industrial context. This key Japanese term is made up of the words for “change” (Kai) and “for the better” (Zen). Accordingly, continuous improvement processes aim to provide a working environment which openly accepts mistakes. If something isn’t running smoothly, it is perceived as an opportunity to improve rather than a reason to get annoyed.

It is important to note that CIP isn’t aimed at major errors but often at small details because, let’s be honest, nothing is perfect. In this respect, CIP aims to hone everyone’s senses and employee participation is vital to achieving this. Employees observe processes first-hand right where they happen, the place referred to in lean production as “gemba”, and are therefore in the best position to judge where there is still room for improvement. You only need to look closely.

7 Muda: Avoiding waste

A further fundamental principle of the lean methodology is that if you want to optimise your own processes, you need to actively tackle waste. In Japanese, “Muda” refers to a useless activity in the sense that it does not help to create value. According to the 7 Muda, waste can be avoided in the following ways:

- Don’t move materials around needlessly

- Reduce warehouse stock

- Avoid movements that are not ergonomic

- Cut down on avoidable waiting times

- Simplify processing

- Continuously improve

The above list clearly demonstrates how closely intertwined the individual lean production methods are. The 7 Muda provide key approaches to recognising areas in need of continuous improvement. With that said, you also need to know how to tackle waste in practice. Merely recognising the different forms of waste is not enough.

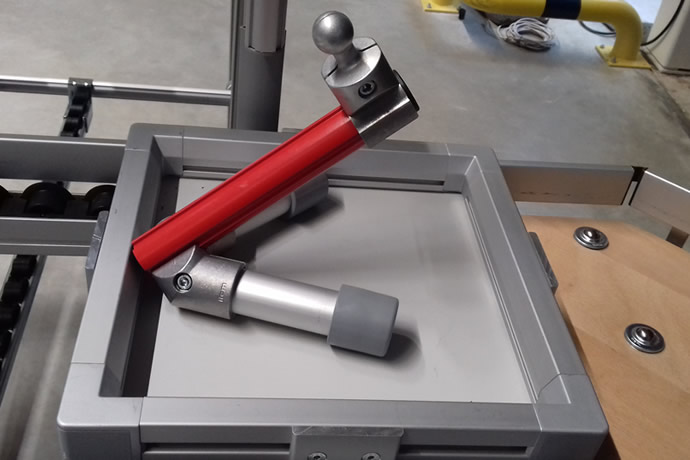

Using the 5S method to establish standard processes

Whilst CIP remains rather abstract and provides the conceptual framework, lean production methods such as 5S show what is vital in practice. The 5S method serves to standardise processes to ensure a designated output within a designated timeframe and with 100% quality. For example, 5S establishes stable processes that help to reduce throughput times. In addition, standardisation creates a basis for continuous improvement. Toyota employee Taiichi Ōno once said: “Without standards there can be no continuous improvement.”

5S owes its name to the individual words that make up the method and which each begin with an “S” in Japanese:

- Seiri: Remove everything that is not needed.

- Seiton: Set up working material ergonomically and label it.

- Seiso: Always clean your own workplace and do so thoroughly.

- Seiketsu: Clear up regularly to prevent disorder.

- Shitsuke: Always be disciplined.

There are numerous benefits to successfully implementing 5S. Besides increasing productivity and quality in assembly, using working spaces more effectively and maintaining a tidy workspace will generally also boost employee motivation. You can arrange your next customer visit at any time, without any nasty surprises.

Are you interested in fascinating reports and innovations from the world of lean production? Then we have the perfect solution for you – simply subscribe to the item blog by completing the box at the top right!