Algae farming is a new and highly promising branch of the life sciences sector.

Algae farming has become increasingly important in the pharmaceutical and nutraceutical industries over the past few years. Numerous types of algae possess properties that can boost our immune system, which opens up a new pool of active ingredients that have yet to be put to use. Manufacturing such ingredients, however, places high demands on factory equipment – as item discovered when it designed a modular enclosure solution for six photobioreactors at Wrocław-based Algae Labs Sp. z o.o. Microalgae are grown inside these bioreactors to derive astaxanthin – a reddish and naturally occurring substance that is produced by Haematococcus pluvialis and is classified as a carotenoid. Astaxanthin possesses antioxidant properties and offers high UV protection that cannot be washed off – which explains why it is proving very popular among athletes in particular.

Algae farming has special requirements

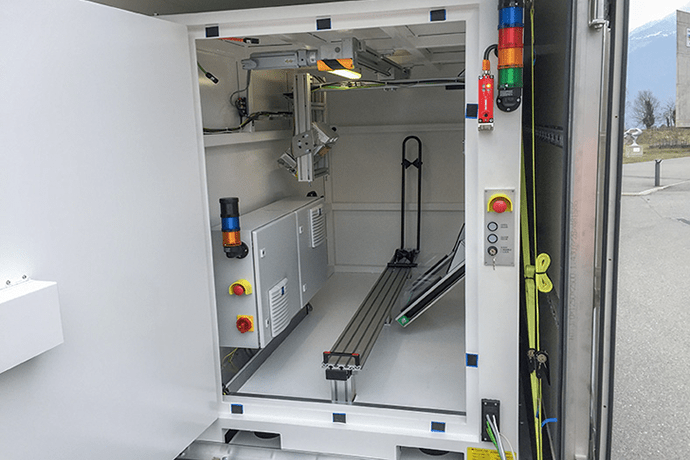

Up-and-coming Polish company Algae Labs currently employs eleven workers and focuses on researching and developing the microalga Haematococcus pluvialis as well as producing and commercializing astaxanthin. Planning the new modular enclosure for a station with photobioreactors for manufacturing biomass involved meeting special requirements. Besides factoring in the dimensions of the six installed plants – 250 cm x 5 cm x 5 cm – the enclosure design also had to accommodate their 250 kg weight. Being able to ergonomically remove the heavy cultivating containers was a must, too. Another key factor was ensuring the factory equipment remained sterile, as the microalga is susceptible to contamination from other algae, fungi and bacteria. This meant the equipment had to be assembled under cleanroom conditions.

To ensure the containers could be cleaned thoroughly and regularly, the modular enclosure also had to be engineered so that the photobioreactors could be easily taken out and replaced at any time. In keeping with these requirements, planning focused on a design that used the aluminium profiles from the item Line X. Thanks to the multi-chambered frame, lab technicians can control individual algae farming processes separately. The unbroken surfaces and the minimised edge radius that ensures a seamless transition between individual profiles make Line X perfect for applications that demand high hygiene standards. Once the algae has been cultivated, the design ensures the bioreactors can be safely and ergonomically removed.

Perfectly suited to life sciences

After item staff had prepared the modular enclosure, Algae Labs saw to the assembly themselves. The team members from the Polish laboratory were extremely satisfied with our profile technology’s properties and immediately won over by the modular structure, intercompatibility and high-quality design. This fruitful collaboration to plan and install the modular enclosure has led to even more applications being jointly implemented. Michał Grzebyk, Deputy Director of Algae Labs, strongly believes that the solutions from item are well-suited to the life sciences sector because they support customised engineering that factors in laboratory requirements. Assembly is done under cleanroom conditions and there is always the option of making last-minute changes to projects that have already been designed.

Do you want to keep up to date on innovative ways that item solutions are being put to use? Then we have the perfect solution for you.

Simply subscribe to the item blog by completing the box at the top right!