Having recently shed light on ergologistic® – the interaction of ergonomics and intralogistics – we’re now going to take a closer look.

Our focal point today is the internal material flow as such. This plays a key role in optimum production efficiency, which means very high demands in terms of up-to-date intralogistics. Despite the Latin prefix “intra” meaning between, intralogistics by no means exists in a secure bubble. It is affected by outside factors and is subject to significant external pressure. Consequently, one cog needs to interlink perfectly with the other – because delays quickly cause problems. In addition to consumption-driven material provisioning/picking and employee involvement, the properties of factory equipment are also key.

Less waste for a better material flow

To ensure a smooth internal material flow, it must be possible to adapt all intralogistics processes at any time. This flexibility must not, however, negatively affect the stability of the material used. If equipment frequently breaks down and needs to be repaired, this results in costs that are absolutely avoidable – waste in other words. The 7 Muda anti-waste concept explains how to avoid such traps. Simply considering the efficiency-boosting principles of lean production on a methodological level isn’t enough, though. Anyone who is looking to optimise the internal material flow needs to pay specific attention to flexibility and durability in factory equipment engineering.

The technical side of intralogistics

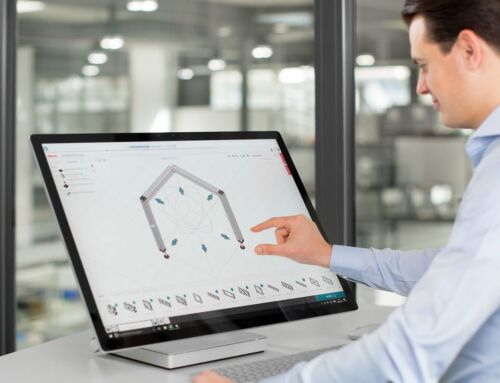

This leads directly to the core element of modern-day intralogistics equipment – solutions and above all optimisations are quickly achieved with modular profile technology such as the Lean Production Building Kit System from item. One tool is sufficient to make relevant adjustments (to a transport trolley, for instance) while maintaining a constant level of stability. Consequently, the fasteners do not need to be retightened and creep is not a problem either. This dispenses with unproductive waiting times, not to mention potential safety risks due to connections that in the worst-case scenario work loose while in use. Thanks to cutting-edge intralogistics, technical uncertainty can thus be removed from the internal material flow.

Want to keep up to date with everything that’s going on in the world of item?

Simply subscribe to the item blog by completing the box at the top right!