Selecting and configuring Linear Units usually involves a great deal of effort, but the state-of-the-art MotionDesigner offers valuable assistance.

When selecting a linear unit and drive component in process automation, there are several key aspects to consider. These include properties such as speed, payload, and stroke length to factors like area of application and duty cycle. Choosing a suitable linear unit and corresponding drive component can be a complicated and time-consuming task for engineers. Configuring these often complex systems calls for in-depth expert knowledge as well. The right online tools make the entire process easier, offering targeted support with everything from the initial selection through to commissioning. Discover how the item MotionDesigner® aids in the creation of strong automation solutions for everything from multi-axis gantries to pick-and-place operations.

More Efficient Automation

More Efficient Automation

Download the free Automation Factsheet on Linear technology applications, providing a compact overview of solutions, components, and the numerous uses of item linear technology.

1,000 Combination Options, One Recommendation

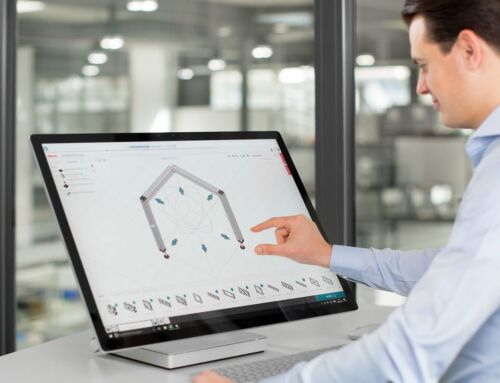

item Linear technology is revolutionizing the way automation solutions are planned, built, and commissioned. The MotionDesigner® is changing the way those automation solutions are designed. Based on your specifications, the configuration software finds the linear unit that suits your application in a matter of seconds.

Let’s explore the advantages of online tools like the MotionDesigner®:

Creating parallel motion applications

Synchronized linear units are the ideal solution to demonstrate the advantages of item online tools. These solutions are often the perfect choice for applications that require cantilevers or carriages to move in parallel, which several options for implementation.

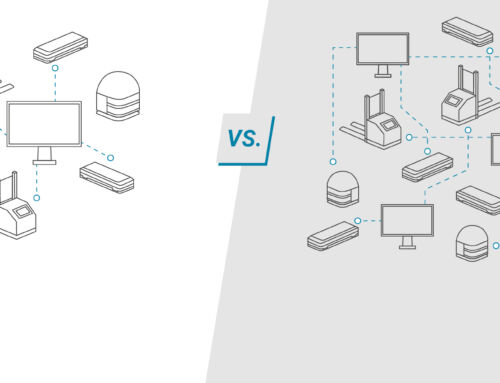

The first option would be equipping each linear unit with its own drive and installing a PLC (programmable logic controller) to regulate synchronization. The easier and more cost-effective option, however, would be to connect the linear units via a shaft and use a single motor. This second option, while easier, makes the design process more complex and necessitates finding suitable couplings and drive shafts for the chosen linear units and drive components. Not only that, but engineers must also determine the torque load during acceleration and braking maneuvers.

Mechanically synchronized linear units can be easily tailored to the transport task at hand via the MotionDesigner®. Intelligently determining the perfect combination of two linear units and one synchronizer shaft enables two carriages or two linear units to be moving in parallel.

Light work of choosing linear components

The MotionDesigner® offers support for dimensioning and selecting components. For example, it calculates the maximum torques and recommends a solution with a suitable coupling. The intelligent program also notes the correlations between the length of the synchronizer shaft and the maximum speed of the synchronized linear axes. In addition, the linear technology configurator determines the necessary length of the synchronizer shaft and dimensions of a housing, if required.

As the load between two carriages of synchronized linear units can be unevenly distributed, the MotionDesigner® provides a detailed description of forces generated while also taking into account the torque load during acceleration and breaking maneuvers. The software’s comparison function enables users to see both the technical requirements defined by the data they input and the technical specifications for the system recommended by the manufacturer. Systems designed in this tool deliver optimum speed, precision and load-carrying capacity while also running efficiently over the long term.

Easier on your Engineers

Engineers can choose between the system that matches their requirements exactly and alternatives that offer larger power reserves. The configurator makes it considerably simpler to specify systems, providing an ideally dimensioned turnkey solution. The MotionDesigner® automatically creates a complete set of documentation with all the technical details and CAD data. Engineers can also draw on numerous example applications, including construction data.

Data generated in the design process is immediately available when commissioning linear units with this solution. The software automatically determines the best possible controller settings and checks the coordination of the parallel linear units in a test run, meaning a system made of synchronized linear units can be up and running in minutes. The team of item Experts creates an available help system, providing users with comprehensive support and specific answers to any questions regarding parametrization and commissioning.

Interested in more information on item tools that can simplify your processes while ensuring speed, reliability, and precision? Receive the latest item innovation by completing the box at the right-hand corner!