It’s not unusual to find cable conduits here and there in the home, but in industry they are absolutely indispensable.

Virtually every industrial work bench needs energy in one form or another. It is essential to ensure network cables are installed and there is a reliable supply of power and compressed air. A cable conduit will protect these cables and hoses from damage and dust, while its neat format also makes installation work easier, with supply lines being routed above or below the working surface as required. At the same time, high-quality cable conduits also eliminate trip hazards, prevent cables from becoming a tangled mess and keep everything looking neat and tidy. This is yet another area where the hallowed pairing of form and function really counts. However, exactly what sort of cable conduit solutions are used in industry and what other options are there for supplying power and data to the work bench?

Profile technology for optimum supply lines of all types

When cable conduits for industrial applications need to be flexible and fit for a specific purpose, you need to use the right profiles to build an appropriate construction. For instance, there are profiles with an integrated conduit that are ideal for constructing frames with built-in cabling. When using these profiles, the cables are safely concealed within the profile. Another option is to use a modular conduit system. In this case, special support profiles form the base and lid of the system. Special inside-corner pieces help stop kinks developing in cables as they branch off in different directions through industrial conduit systems and also cover over sharp, cut edges. These products create versatile conduits that offer an ideal solution for laying not just cables but also hoses, since many industrial applications require a supply of compressed air in addition to electricity and data.

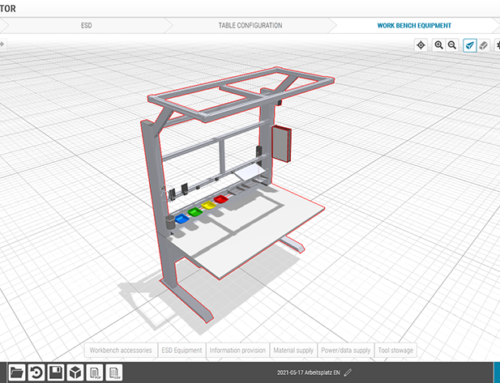

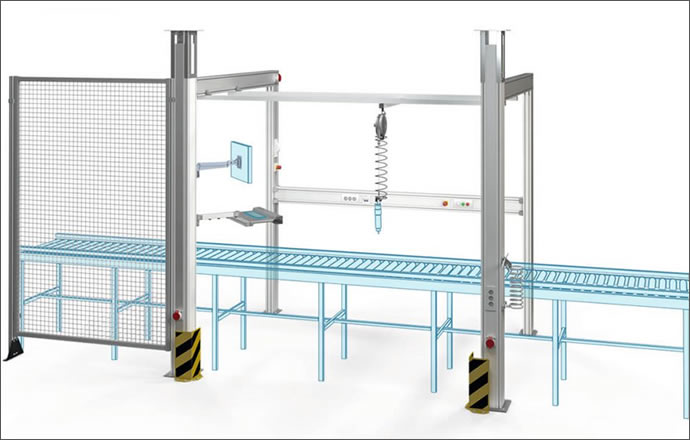

To meet these application requirements, item has developed the Installation Column Profiles. The large Installation Column Profile 8 160×160 K76, for example, features two generous cable conduits and integrated aluminium ducts designed to carry compressed air. The opening on the cable conduits also accommodates Mounting Boxes, Sockets, Keystone Modules and Switches, which are simply clipped into place, with no need for machining. A whole array of different installation column variants can be built using these profiles. They can be used as multi-functional supply hubs or as integral parts of machines and workstations. Virtually any work bench can be customized by positioning plug sockets and compressed air connections as needed. For example, an Installation Column can be integrated directly into a safety guard – with an emergency shutdown system and fixings for emergency equipment such as fire extinguishers.

Thanks to its modularity and compatibility with the mb building kit system, the installation column is exceptionally versatile.

Much more than just a cable conduit – industry opts for Installation Profiles

The versatility of Installation Columns becomes increasingly clear when you start to look at specific examples. A variant we call the supply solution is the ideal option for providing the all-round essentials in industrial workshops and logistics facilities. It boasts a securely integrated compressed air duct and incorporates 230 and 400 volt sockets. By contrast, the logistics solution is geared entirely toward the challenges that logisticians meet on a daily basis. Attachments ranging from a Monitor Arm to a Tablet Holder ensure materials and data are always close to hand. Further accessories were launched in autumn 2019, such as Table Top OCTA 25-1110×555 and Table Top 25-900×450, each of which is attached to the column using Table Top Support Set 8 420-45°. The Line 8 system groove on the column also offers an adaptable fixing option for a whole range of additional accessories from the item building kit system.

The Installation Column is also equipped for use in automated production plants and conveying systems, in milling and sawing environments and in other areas with increased safety risks. The safe solution, for example, ensures users can easily incorporate safety elements such as status lights. The same applies to accessories such as impact protection features and emergency off or stop buttons. Frames and holders can also be used to display safety instructions and mount emergency equipment.

The data solution provides a central access point for email, internet and intranet when employees in industrial production areas and workshops don’t have their own fixed online access or PC workstations. A Monitor Arm and a Pivot Arm for keyboards make it even more user friendly. Lastly, the horizontal solution can be used to integrate switches and power and data sockets neatly into a work bench. This ensures control circuit devices can be incorporated in very close proximity to machinery. item Installation Profile 160×80 K76 can also be used as table-top trunking or built directly into industrial work bench systems.

Interested in applications and solutions from item? Then we have something that’s right up your street!

Simply subscribe to the item blog by completing the box at the top right.

.