Networking, researching, and training – the Mehnert Lab in Erfurt sees itself as a platform for industrial cooperation in the age of Industry 4.0.

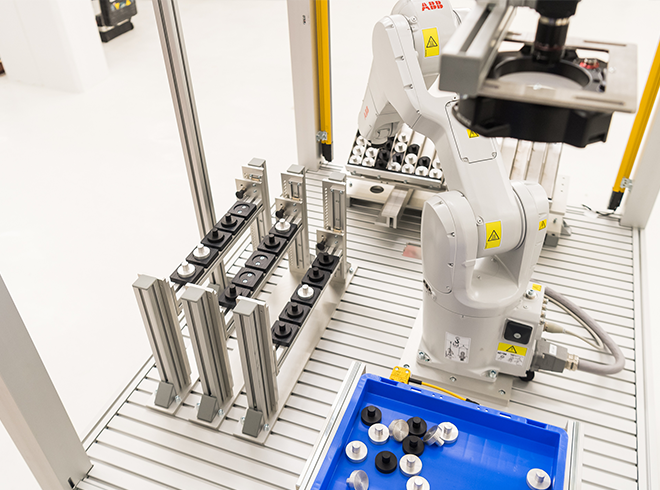

Mehnert GmbH provides skilled workers and specialists for various projects in the fields of electronics, mechanics, digital control, 3D measurement technology, and robotics. The company employs 55 permanent staff members, headquartered in Mülsen but also represented in Erfurt. The globally-deployed team is focused on the construction, maintenance, and servicing of modern industrial plants. A few years ago, Managing Director René Mehnert founded the Mehnert Lab in Erfurt. It facilitates a new form of industrial collaboration and creates the perfect working environment to provide specialists with the best possible qualifications. In addition to modern seminar rooms and areas for events and workshops, a 600-square-meter area is available for machine and plant technologies, with various robot and control systems common in mechanical engineering.

Components and Modules for Equipment

In the summer of 2019, René Mehnert was seeking suitable partners for equipping the lab.

The goal: creating an optimal basis for experimental setups.

The solution: machine cells were to be created that can be operated autonomously as well as interconnected in order to simulate a complete production line. “I was looking for a local supplier who could deliver aesthetically pleasing components that were stable yet flexible,” says Mehnert. “item quickly came into play. In addition to the unique design and functionality of the components, I was convinced by the quality and easy compatibility as well as the huge catalogue.”

Individually Configurable Machine Cabins

With its location in Mühlhausen, item is just a few kilometers from Erfurt, putting it in close proximity to the Mehnert Lab. Initial designs for the lab equipment were created in collaboration with a local design office. For the 600-square-meter area, booths measuring 1.6 meters wide by 2 meters high were prepared for the use of robots. For this, item supplied numerous components from the item MB Building Kit System, such as grooved panels, robot mounting plates, aluminum profiles and connectors, as well as hinges and other accessories.

“The item components laid the foundation for easy integration of other systems,” said Steve Syhre, Project Manager at item. “Several superstructures made of profiles, with mounting options for robots and the entire frame for the lab cells were implemented.”

The control cabinets with corresponding electronics are located in the lower area of the machine cabins, with doors and flaps made of item components. Above the work areas, which can be viewed from all sides, a frame made of 80x80m aluminum profiles hold a stable grooved panel. These areas are still fitted with transparent elements, so that the interior areas are protected. Supply lines run inside the cells via item columns.

Convenient Flexibility and Modularity

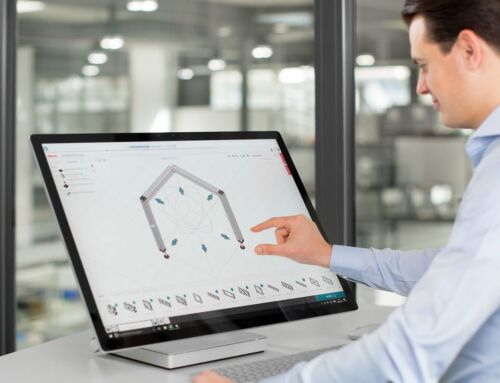

While item collaborated with the design company to handle planning, the cutting of the components and cell assembly were carried out by Mehnert employees. Their team got hands-on with the portfolio of the Original Machine Building Kit System, and also used the item Online Tools for numerous tasks.

“We provide the framework with our cells, but can also expand and resize them as needed,” explains René Mehnert. “Accordingly, customers benefit from an environment in which projects can be implemented easily and conveniently.”

Each of the eight cells can be operated autonomously; however, since Mehnert can arrange the individual cells next to each other, a complete production line can also be created. The systems are not rigid, but can be adapted to respective requirements. In doing so, Mehnert draws on the item portfolio of over 4,000 components and growing. The large portfolio offers more opportunities for configuration to customers, which for Mehnert means the customer can optimally design the machine cabins according to their own specific requirements.

“The particular advantage of the [item] components is clearly their extremely fast assembly and disassembly,” says René Mehnert. “Constructions made of welded profiles don’t provide this flexibility.”

Another advantage of item? Older profiles can be easily combined with newer profile. “This means that it’s not necessary to change the product range every 5 years, for example,” explains the managing director. For him, the visual appearance also plays a major role: “Our constructions still look as if they were made of one piece, and will even in 30 years’ time, thanks to the smooth surface and the elegant design of the aluminum profiles.”

A Win-Win Situation

During the entire project, item remained in close contact with Mehnert. “We really appreciate the partnership and intense support from item,” emphasizes René Mehnert. “item was always there to help us in word and deed. This enabled us to find solutions quickly, even in difficult situations.” Currently, not all cells have been completed. Beyond that, however, a continuation of the collaboration is already being considered to present additional components from the areas of lean production or workplace systems.

“We see the Mehnert Lab as a permanent exhibition for companies to showcase their products and innovations,” said René Mehnert. “It is virtually equivalent to a trade fair that takes place 365 days a year.” In the process, the robot cells are rented out to interested parties for a certain period of time. This way, employees can be trained across companies, but startups and universities are also able to use the available equipment for their own projects. Ultimately, different companies and institutions are able to come into contact with item components – a win-win situation for all involved.

Whether through new business models, innovative service concepts, or application-oriented practical solutions, the Mehnert Lab creates space for creative ideas. This provides opportunities for digitalization and global competition to be made tangible. “Our goal is for several companies with different technologies to work in the Lab and benefit from each other in order to advance each other’s projects,” notes René Mehnert. “With the item components, we provide an ideal platform for this and, with our Lab, offer opportunities for a lively exchange of information as well as optimal sales opportunities beyond that.”

Interested in More?

Mehnert Lab is one of several companies who have created innovative machine structures with item components. Discover more of these secure structure success stories like this one on the item blog, and receive the latest innovation in your inbox by completing the box at the top right.

Or, discover the item Solution Center where you can browse preconfigured solutions like these machine structures and secure cabins.