It really gets under your skin – thousands of single-use needles are required in doctors’ surgeries and clinics every day.

Whether they are used for blood tests or injections, no other object is as closely associated with medicine technology as the syringe. As is often the case in the life sciences industry, producing single-use needles and syringes means that two very different concerns have to be taken into account – zero tolerance of hygiene issues and cost-effective production. The Dresden-based company Konstruktion Maschinenbau Vorrichtungstechnik (KMV) Müller has designed and built a sophisticated pick-and-place machine for a pharmaceutical industry customer that meets precisely these requirements.

GMP with Line X from item

For item pluspartner KMV Müller, the major challenge in designing the machine lay in the demands placed on machinery used in the pharmaceutical industry. Top priorities in this field include minimising any potential for machines to get dirty or contaminated, and ensuring easy cleaning for the entire system. Machinery manufacturers must comply with Good Manufacturing Practice (GMP) guidelines, which regulate all processing stages. The tried-and-tested Line X profiles from item proved to be perfect for this application.

Pick-and-place systems are automated workpiece positioning systems. They can be used to select a required part from a large number of other workpieces. The part is then transferred to a defined position for further processing. The KMV Müller machine is used to individually select single-use needles to be attached to syringes in medical surgeries. The sterilised, approx. 60 mm long needles are fed into the machine as bulk material.

Precision and speed

The pick-and-place machine is therefore fitted with a “stock bunker”. With the help of a conveyor belt, the needles are transported into a centrifugal feeder and positioned precisely. A linear conveyor then transfers the sorted syringe pieces to the release system. Here, two grippers ensure that the individual workpieces are positioned within the release system cleanly, and that they do not get so close to each other that the dynamic pressure causes them to tilt as they are transferred to the next stage.

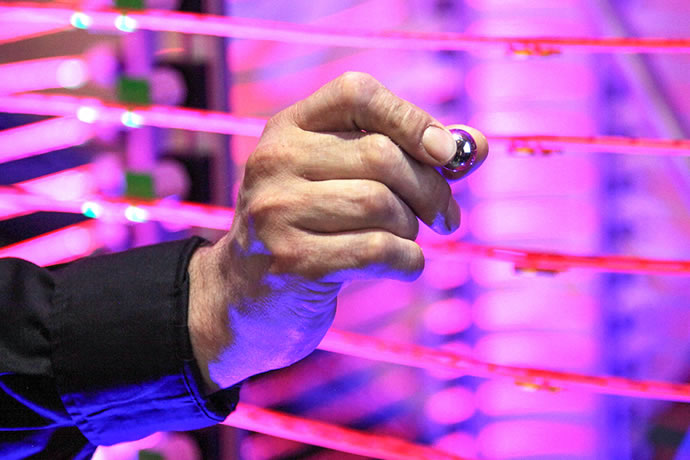

Next, a robot equipped with vacuum cups extracts the single-use needles from the release system and places them into a sequencing chain. The machine is fitted with its own operating console for individual programming. The signal tower uses different lights to give operators a quick and clear overview of any faults (red), material bottlenecks set to arise within 15 minutes (blue), or problems with a pre-process machine (yellow).

Life sciences engineering with item

Operating at a rate of 100 units per minute, this is an exceptionally efficient yet still remarkably quiet machine. Thanks to the use of an enclosure made with item polycarbonate panels and a conscious decision to use low-noise feed and transport components, it complies with the recommended occupational health and safety noise level of 70 dB. Since KMV Müller first installed and commissioned the machine, it has run without any faults and is regularly maintained by the pharmaceutical company’s technicians.

This article first appeared on the item pluspartner blog. Do you want to keep up-to-date with how item is bringing lean production to the life sciences industry ? Then we have something that might just help – simply subscribe to the item blog by completing the box at the top right!