The city of Suzhou in China is not just a booming metropolis – it’s also home to a very special lean line design training course.

Learning the theory behind lean production methods is a good start, but gaining hands-on experience is a must. As we’ve discussed in previous posts, there are lean training courses specially designed to let participants do just that. For example, we’ve covered the CETPM and the practical course in lean assembly run by the Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University. In this article, our search for lean line design training courses takes us to Suzhou – one of China’s booming economic hubs and home to the Smart Manufacturing Labs of GAMI (Global Advanced Manufacturing Institute). GAMI was founded by the wbk Institute of Production Science, which is part of the Karlsruhe Institute of Technology. The institute has a long-standing strategic partnership with item and uses Profile Tube System D30 in an intensive lean line design training course.

item-based production line used for intensive lean line design training

GAMI’s lean line design training course, which is held twice a month, is designed to help participants apply their lean production expertise when designing production lines. The first part – intended as a refresher or introductory course – covers the basics of lean production. This includes the history of lean production, key lean terms such as Kanban and visualization methods such as the spaghetti diagram, which can be used to map how staff and products move around at the Gemba. The Gemba is the place where value is created – or waste (Muda), which lean production aims to minimize. The second part of the course directly ties in with these basic concepts and focuses on creating a lean production line. A tour through GAMI’s smart manufacturing lab was integrated in the course as well, so the participants can get an impression on the future of smart manufacturing. They also receive inspiration for their long-term strategy.

The participants then move onto an assembly line based on item components, where they have to put the knowledge they’ve learnt in the lean seminar into practice to optimize the line. Profile Tube System D30 is the ideal solution for this. Thanks to its modular design and flexibility, the participants can try out lots of different things and make quick modifications. The product being assembled – our FIFO dog (FIFO = first in, first out) – is made of components from Profile Tube System D30, too. Furthermore, GAMI also values the options that the item Engineeringtool opens up when it comes to digitally engineering factory equipment for lean production lines.

The best of both worlds – Industry 4.0 and lean production

GAMI was founded in 2008 by Prof. Gisela Lanza in China. Due to its university background, the institute is ideally equipped to provide its partners with advanced methods and concepts for achieving operational excellence. The goal is always to develop customized strategies and smart solutions for smart production and management, quality management and supply chain management. The Smart Manufacturing Lab, which is also where the lean training course is held, serves two functions in this regard. Firstly, it offers a venue that can host educational courses of the highest standard. Secondly, it acts as an incubator for countless events centered around smart production that are staged jointly by German and Chinese organizations. For instance, GAMI’s Industry 4.0 Demonstration and Innovation Center was the very first research center in China to showcase Industry 4.0 solutions in live operation. After all, lean production and Industry 4.0 are by no means mutually exclusive.

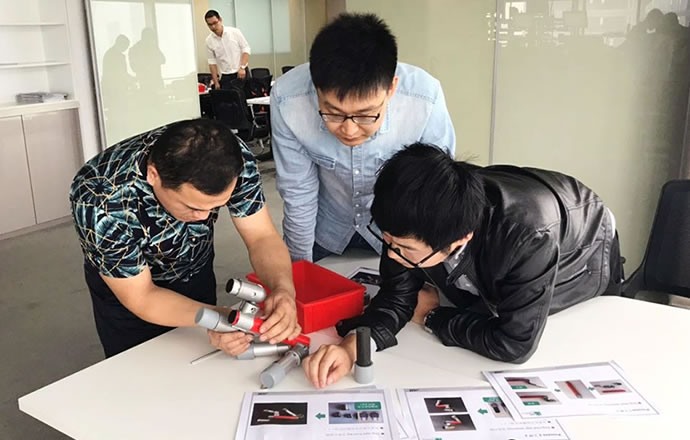

Three participants assembling the fifo dog as part of the lean training course.

Are you interested in fascinating reports and innovations from the world of lean production?

Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right!

.