Complex structures and entire objects appear as if from nothing – 3D printing never fails to impress. The innovative technology can also be useful when building prototypes.

Whether jewellery, textiles or prostheses, the possibilities that 3D printing offers seem to be growing all the time. There is currently even a drive to print whole buildings, which is known as contour crafting. The process discovered by American Chuck Holl in 1983, when it was referred to as stereo lithography, seems to have since developed into something from a science fiction film. All the same, it doesn’t always have to be spectacular – quite the opposite, in fact. 3D printing also unlocks striking possibilities in mechanical engineering, an area known for being down to earth. The following piece on three-dimensional printed prototypes explains …

What 3D printing is all about

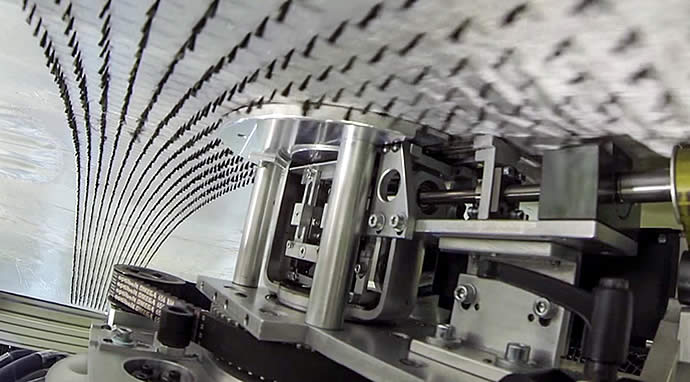

Using CAD data as a basis, 3D printers print several layers of a material such as plastic, metal or ceramics one on top of another. In an industrial context, 3D printing is also referred to as “additive manufacturing”. Unlike subtractive processes, which rely on the removal of material, one of the key features of additive manufacturing is its very economical use of materials. For example, while CNC processing requires that a certain amount of material is milled away, 3D printing uses only what is actually needed.

Rapid prototyping – added certainty for engineering

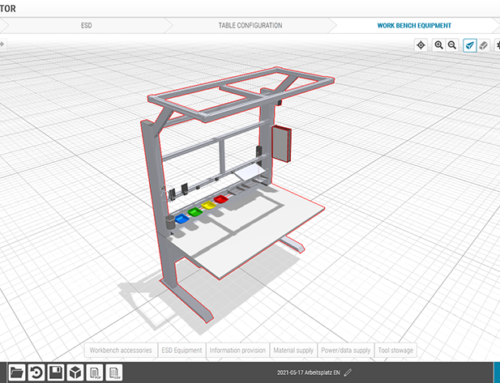

Rapid prototyping is a direct reaction to the rapid throughput cycles that dominate industry, leaving no time to manufacture pre-series parts or models. Fundamentally, rapid prototyping has the same objectives and advantages as conventional prototype building. It is about studying preliminary versions of parts to identify potential weaknesses at an early stage. This smooths the transition between planning and engineering stages, thus avoiding the high costs that could arise as a result of manufacturing faulty parts.

The precision and speed of 3D printing makes it perfect as a rapid prototyping technology. However, in the electronics sector, it is important that all the materials used are also ESD-safe. Unfortunately, conventional 3D printing materials do not exhibit the crucial properties that are necessary. There is an easy way around this problem though – carefully applying a surface coating to printed prototypes protects them against electrostatic discharges. Brittle, simple plastics are basically the recommended materials for 3D printing.