Countless trainees are being taught at modular aluminium work benches at CHEMPARK.

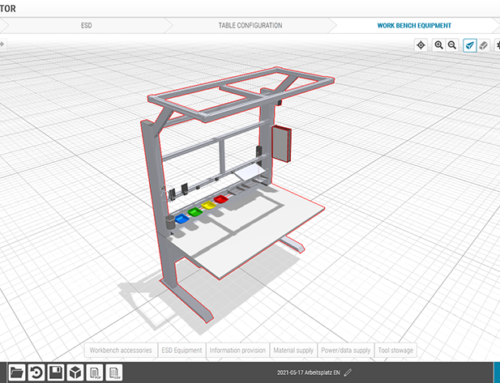

CURRENTA is known, first and foremost, as the manager and operator of CHEMPARK, with sites in Leverkusen, Dormagen and Krefeld-Uerdingen, covering a total area of 11 km2, where some 48,000 employees from 70 different companies work everyday. There’s no shortage of trainees on site, either. The CURRENTA training campus at CHEMPARK prepares young people for a wide variety of professions, including budding chemical and lab technicians, plant mechanics, electronic engineers and businesspeople. CURRENTA also cooperates with other companies represented at CHEMPARK, such as LANXESS, Bayer and Covestro. For the 1000 trainees currently at the Leverkusen site, the road to vocational training is a short one – with the CURRENTA Vocational School located right on campus. CURRENTA uses the modular MB Building Kit System from item to build the work benches where its trainees gain hands-on experience.

Ready for anything

item aluminium profiles are used on the training campus in three specific application areas – in work benches for instrumentation and control (I&C) engineering, in I&C systems and in special work benches for a one-year vocational guidance course. During this guidance period, trainees can get a taste of a wide range of occupations. Those training to become chemical technicians have to put their material processing skills to the test– which involves operations such as filing, sawing and cutting – at a specially equipped, height-adjustable work bench. I&C systems are ultimately used to set controllers and check system parameters.

A total of 48 work benches based on the item MB Building Kit System are currently in use at the CURRENTA training campus. Besides creating bespoke solutions, ensuring versatility was also a key deciding factor, as Kai Roland Fliessbach, responsible for training future production workers, points out: “We always want to be flexible – that way, we can adapt or remove a particular element to suit the current circumstances. We may have to modify the dimensions of our work benches. Thanks to the MB Building Kit System, we’re able to make the necessary structural changes quickly and easily.” He highlights the difference between this modular, flexible solution and a fixed, off-the-shelf work bench that would come with a whole host of restrictions. “We’re also extremely pleased with the customer support item offers. It’s a very quick turnaround – our contact sees to us directly and is on site in no time at all. We never struggle to find the perfect solution,” says Fliessbach.

the image shows a pressure control system (left) and a temperature measuring unit with built-in display in front of a level measurement system that uses the bubble principle (right).

Do you want to keep up to date on the various ways that item solutions are being put to use? Then we have the perfect solution for you. Simply subscribe to the item blog by completing the box at the top right.