Lean production in practice – what is a “Gemba walk”?

If you explore Japanese culture, you’re sure to come across the term “Gemba” in a whole range of contexts. It can be loosely translated as “the actual place”. Traditionally, the term refers to the place that is at the heart of an activity or observation. For journalists, the Gemba is the place where an event has occurred. For the police, it is the scene of a crime. Since lean production is all about boosting value creation, the Gemba in this context is production – that is the most important place in a plant, because it is where the company earns its money. This is where the continuous improvement process (CIP) needs to be implemented and care taken to observe the 3Ms (Mura, Muri and Muda). Naturally, this leads to the question of how the management team can best keep up to date with what is happening at their Gemba, which is where the “Gemba walk” comes into play.

Gemba walk – taking you to the place where value is created

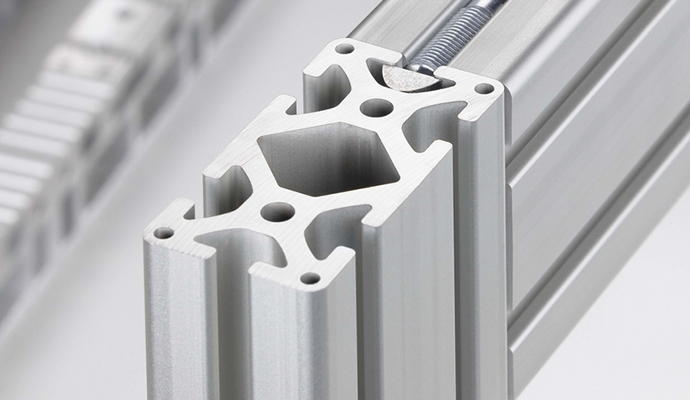

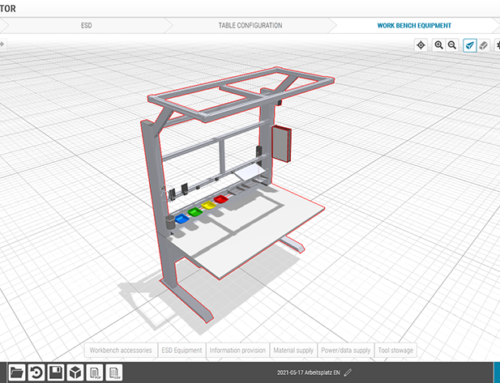

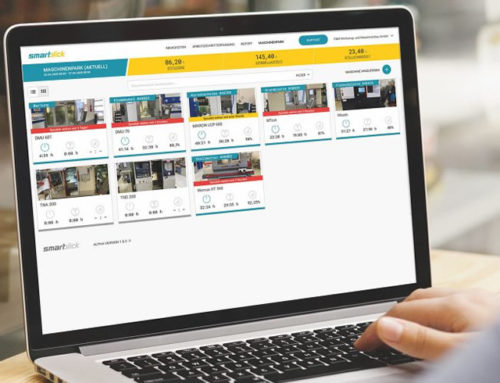

One of the core principles of CIP is having a better appreciation for individual staff members. They are the people who have the best idea of where waste, imbalance and overload are to be found in the company. This practical, first-hand knowledge can only be gained by being right there on the ground, where these issues arise, i.e. by being at the Gemba. Workers are then quickly able to adjust factory equipment, especially if they have the latest generation of flexible lean production building kit systems at their disposal. A good way to ensure this know-how is passed on is by conducting a Gemba walk, which is when managers visit the place where value is created for themselves so they can get an overview. The walk involves seeing what is going on, making notes and talking to the team.

However, Gemba walks are not about checking up on staff and should never be used as a response to a specific problem. Instead, they should be a part of the normal working routine. After all, a key premise of the lean philosophy is that achieving an ultimate state of perfection is impossible – there is always room for improvement, so there will always be a need for Gemba walks. Just like all the other lean production methods, they are an expression of a positive fault culture. This stems from Kaizen, the traditional Japanese principle that translates as “change for the better”. What’s more, there are also social and motivational aspects to a Gemba walk.

Genchi Genbutsu and the Gemba walk

A Gemba walk centres on what the Japanese call “Genchi Genbutsu”, or “go and take a look”. This principle can be traced back to Taiichi Ohno (1912-1990), the father of the Toyota Production System. Ohno said that he always carried a piece of chalk with him, and there is a very revealing anecdote associated with this habit, albeit one that crops up in different versions. However, regardless of whether it was a newbie or the senior engineer who was held responsible for a machine that was consistently underperforming, Ohno is said to have drawn a circle on the floor with his chalk. He then instructed his counterpart to stand in the circle, observe their surroundings and take notes. If Ohno wasn’t satisfied with the notes, the person in question could spend hours in the chalk circle. Now, you can make of that method what you will, but it certainly underscores the importance of the Gemba. In Japan, “Genchi Genbutsu” is used as a synonym for Gemba walk.

Management by wandering around (MBWA)

There is another method that aims to ensure the perspective of the management team is not clouded by too many layers of abstraction and too much second-hand information. It developed independently of the Gemba walk and is known as “management by wandering around” (MBWA). Admittedly, MBWA is less systematic, but it is worth taking a look at if you are interested in lean. Although it was developed in the 1970s at printer pioneer HP, the method was given its snappy name in the 1982 book written by Thomas J. Peters and Robert H. Waterman entitled “In Search of Excellence: Lessons from America’s Best-Run Companies”. MBWA is also based on managers taking a tour of the company and visiting their staff at their place of work. As in the case of the Gemba walk, the purpose is not to check up on employees, but rather to show appreciation, bolster communication and thus improve the working environment.

Are you interested in fascinating reports and innovations from the world of lean production? Then we have the perfect solution for you – simply subscribe to the item blog by completing the box at the top right!