Lean production principles can really come into their own in factory equipment engineering.

These principles are geared specifically towards avoiding waste and boosting added value in production. The continuous improvement process (CIP) is a key element, but process optimization in production isn’t just a question of using the correct methodology. Ensuring perfect interplay between method and factory equipment is far more important, so item developed Profile Tube System D30 with this specific purpose in mind. It’s ideal for fast and flexible factory equipment engineering – from a basic frame to a FIFO rack. The long-term stability of the fasteners, simple construction and end-to-end flexibility make your production processes more efficient. You can now start adding value right from the factory equipment engineering stage thanks to time-saving digital engineering with the item Engineeringtool.

The world of lean production

The world of lean production

Less waste and more added value – lean production methods let you make targeted improvements to your production efficiency. Our white paper provides a compact introduction.

Design your factory equipment with ease online

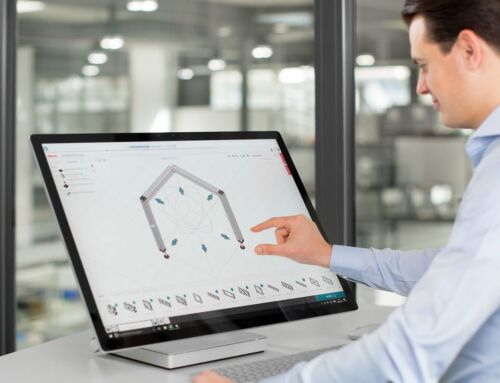

The item Engineeringtool sidesteps the typical technical issues involved in 3D engineering. All you need is an end device with internet access and a browser, so it couldn’t be easier to work from anywhere and start immediately. Functions such as drag-and-drop placement, automatic component alignment and fastener plausibility checks make for much faster digital factory equipment engineering. The item Engineeringtool features a clear, uncluttered interface, so you can incorporate Profile Tubes into your design with ease. The same goes for roller conveyors and many other components.

What’s more, the online tool generates complete project drawings and assembly instructions from your design, automatically providing full documentation. That means you can devote all your attention to improving the material flow. Tedious paperwork is also a thing of the past. Changing a design no longer means having to create a new engineering drawing. You can simply make the change online and save a new version. The item Engineeringtool also makes coordination far more straightforward. Everything is available digitally, so it’s easy to share sketches, drawings and assembly instructions with colleagues anywhere in the world – an excellent way of optimizing CIP-related communication.

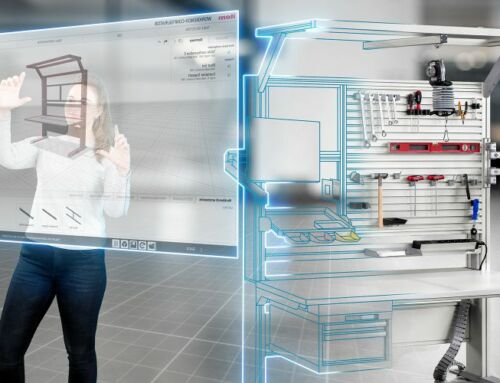

Are you interested in digitization and what the future of mechanical and design engineering will look like? Then we have something that might just help!

Simply subscribe to the item blog by completing the box at the top right!

.