Researching and utilizing artificial intelligence (AI) in an industrial context is currently a key driver of innovation.

To ensure artificial intelligence in mechanical engineering, for example, supports people in their work, it takes a special design approach. Two factors are key to the successful use of AI in combination with other new technologies. Firstly, there must be motivated employees who are trained in handling AI applications. Secondly, the environment must encourage and enable the safe and targeted use of AI. These two factors come together in one of three new research fields in the Organizational Development department of the Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University – “Augmented Intelligence”. The scientists are working here together with national and international partners from research and industry to find AI solutions for production that will provide targeted support for human intelligence. To ensure these solutions for human and artificial intelligence are developed with a close eye on practical considerations, a special research laboratory was recently designed in the form of AIXLAB. This also relies on the ergonomic Work Bench System from item.

Experience innovative AI up close in an escape room

The aim of AIXLAB is to establish a transdisciplinary center for students, researchers, developers and users who understand the potential of artificial intelligence to support people and want to help shape it. The “Escape Room” at the WZL – one of the 2018 winners of the “Working worlds of the future” university competition organized by the German Federal Ministry of Education and Research formed the basis for the AIXLAB concept. The basic idea of the Escape Room was to show the production staff of the future as prototypes.

To this end, a classic industrial work bench was set up as an example and augmented with digital technologies that had been developed in the course of research projects. In line with the fundamental idea behind escape rooms, small groups were tasked with solving practical problems relevant to quality using the technologies provided, so as to be able to leave the room. “This playful approach has demonstrated the benefits and possibilities of digital technologies to vocational school students, university students and representatives from companies, among others,” says the head of the department.

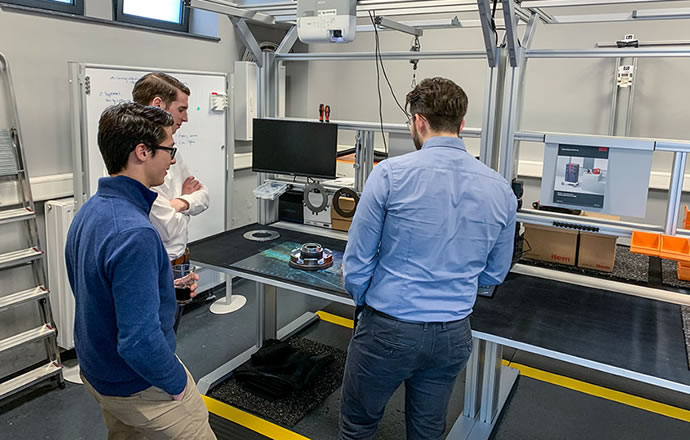

Visitors to aixlab in front of a manual work bench from item.

Humans and artificial intelligence working hand in hand

AIXLAB is the result of the research group’s desire to progress the human-centered use of AI in industrial production. When it comes to the research field of the Organizational Development department and its extended thematic orientation, the letters “AI” stand for Augmented Intelligence. The reorientation of the original concept covers two key aspects that are represented in the name by the letter X: 1. EXperimentation with and 2. EXperience of artificial intelligence. This provides the AIXLAB with two extended versions of its name: “AIXPERIMENTATIONLAB” and “AIXPERIENCELAB”.

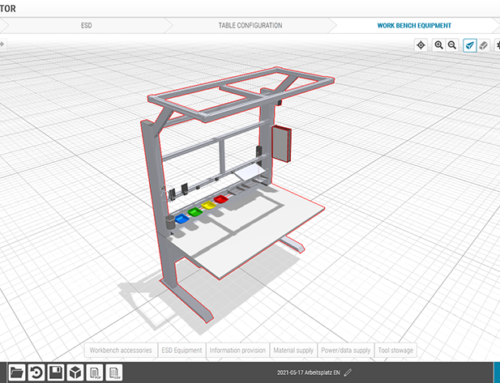

The first test and demonstration field shown in AIXLAB represents a manual production scenario. With the help of item, four modular assembly work benches were set up with ergonomic lighting. The modularity of the work benches offers the ideal basis for meeting the diverse range of requirements involved in experimenting and demonstrating. As a result, the work benches can be adapted with little outlay, for example to conduct studies or test out new findings. The research laboratory for collaboration between humans and artificial intelligence is currently still under construction. Work has been delayed due to the coronavirus pandemic (as at April 2020).

See how well human and artificial intelligence fit together

After being physically constructed in a laboratory setting, the AI-based solutions developed in the current research projects are integrated into the existing test and demonstration field. One example of this is the assembly assistance system from the AuQuA research project. User-friendly support for manual assembly is being developed together with scientists from the Universidade de Sao Paulo. This relies on assembly guides based on augmented reality that can be generated and optimized with the help of machine learning algorithms.

In addition, existing digital technologies (such as AR and VR applications and smart KPI dashboards) are adapted to the manual assembly use case and networked with each other in line with the principles of the Internet of Production. Regular updates about AIXLAB can be found on the Medium Industrial Formation blog.

Are you interested in digitization and future trends such as artificial intelligence?

Then we have something that’s right up your street! Simply subscribe to the item blog by completing the box at the top right.

.