Markets, industries and business models are changing fast. Why not use Scrum as a framework for complex mechanical engineering projects?

The rapid pace of change calls for methods that will meet these challenges, and one word in particular is cropping up more and more – Scrum. Scrum is a project management method that has its origins in software development in the 1990s. The term comes from a set-piece play in rugby, and stands for close collaboration on an equal footing. It is also a term that has become omnipresent in business, particularly in the context of the digital transformation. All the same, people from a whole range of industries are asking themselves if Scrum is really suitable for their specific processes. The many unfamiliar terms can make it difficult to grasp the concept without first taking time to examine the Scrum methodology in more detail. That’s why we want to use this article to provide an introduction to the world of Scrum and highlight how it can benefit the mechanical engineering sector.

An overview of Scrum basics

In the Scrum method, tasks are completed in “sprints”, which usually last 14 days. These tasks – and all the tasks the team has set for each sprint – are listed in the “sprint backlog”. They are described in detail from a customer perspective in the form of “user stories” and broken down into individual subtasks. The team itself decides which user stories to include in the sprint, but in doing so makes a firm undertaking. Before user stories are added to the sprint backlog, they are listed in the “backlog”, which is a kind of archive for outstanding tasks. The backlog is filled by the “product owner”, who acts as a kind of intermediary between the various stakeholders (such as customers and senior managers) and the team, and is responsible for writing and prioritising user stories. The “scrum master”, on the other hand, is not responsible for content, focussing instead on ensuring the rules of the Scrum framework are followed and remedying impediments such as technical problems.

The Scrum Guide also contains a set repertoire of event formats. As the name implies, the “daily scrum” is a daily meeting lasting about 15 minutes, during which the team members report on the tasks they have completed and those that are upcoming. There may be a “follow-up” after this, where news or other important developments are discussed. Before the start of each sprint, there is a “sprint planning session”, during which decisions are made about which user stories are to be included in the sprint backlog. At the end of each sprint, the team presents the results at the “sprint review”. The user stories in the backlog are updated during a “refinement” meeting. Finally, “sprint retrospectives” are held at regular intervals so the team can discuss the situation. It has proved helpful to use a combination of agile project management software and a physical “Scrum board”. User stories, including their subtasks, are stored in the software and printed out. These print-outs can then be placed on the Scrum board and assigned to individual team members using coloured magnets.

Scrum in mechanical engineering – benefits and outlook

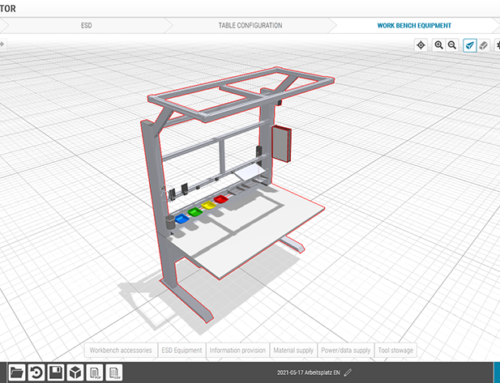

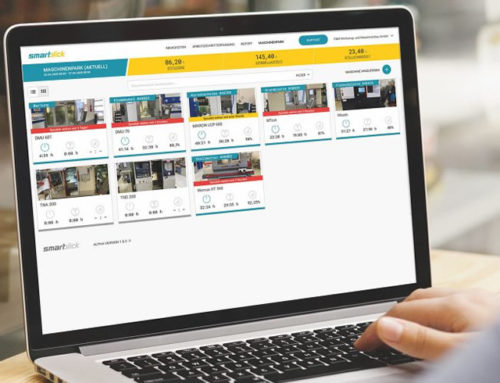

What we have already said about digitalisation in mechanical engineering applies in equal measure to Scrum – one-size-fits-all recommendations are not always possible. Nonetheless, certain guidelines can be laid down. Scrum is particularly well-suited to the product development side of mechanical engineering. Market and customer requirements are constantly on the rise, meaning the time available for developing new products is getting shorter. The definitive customer proximity that is integral to Scrum enables project teams to respond quickly to changing requirements. Mechanical engineering companies are also increasingly becoming software developers. Digital engineering is a perfect example of this. As we noted earlier, Scrum originates from IT development and can be put straight into use without needing to be adapted. You could say it has come full circle.

Innovative combinations of hardware, software and, ideally, also new business models have become an absolute must for playing an active role in shaping the future of mechanical engineering. For companies to survive, they also have to make empowering their employees a top priority. Expertise has never become outdated as fast as it does now. This is another point Scrum has in its favour. It explicitly promotes interdisciplinary working and intensive knowledge sharing. As a result, members of a Scrum team lift each other to new, higher levels of competence. Scrum therefore puts into practice the concept of lifelong learning. Of course, this doesn’t mean that everyone suddenly becomes an IT expert. However, basic IT skills are frequently a prerequisite already, for example in engineering. Whichever way you look at it, it’s hard to see how the mechanical engineering sector can do without Scrum.

Are you interested in digitalisation and what the future of mechanical engineering holds?

Then we have something that might just help! Simply subscribe to the item blog by completing the box at the top right!