Fusing together Karakuri/LCA and robotics opens up new, urgently needed opportunities – as the CETPM is showing in its factory for the future.

These are challenging times for industry. The impact of the COVID-19 pandemic is still being felt, energy costs are skyrocketing and the familiar long-term issues haven’t gone away, either – decarbonization, ever-shrinking batch sizes and shorter product lifecycles. Full automation is not the solution. Instead, more and more companies are turning to Karakuri/LCA (low-cost automation). This lean production method does not usually use drives, sensors, electricity or compressed air. Instead, it relies on spring force, gravity and mechanical principles. As a result, it doesn’t use any electricity, which – given the current energy mix in national grids – reduces CO2 emissions. Compared to conventional automation, the material costs are considerably lower, too. Karakuri/LCA thrives on the commitment and creativity of a company’s workforce, since staff build the solutions themselves and optimize them on a flexible basis.

Despite all its benefits, the range of potential applications for this particular method of automation is limited when it comes to considerable loads and intricate manipulations. However, combining Karakuri/LCA with robotic solutions such as cobots or autonomous mobile robots (AMRs) creates captivating synergies. Prof. Constantin May, founder and Academic Director of the CETPM training institute, is heavily engaged with this topic. The CETPM’s factory for the future is where applications are developed that showcase the potential ways Karakuri/LCA can be combined with robotics. As is the case for all the systems of this type at the CETPM, these applications utilize the Lean Production Building Kit System from item.

Boosting added value with Karakuri/LCA

Boosting added value with Karakuri/LCA

Would you like to discover even more about automation using Karakuri/LCA? Whether you’re a lean novice or an experienced CIP expert, we offer the appropriate support at every level.

Sharing expertise for the future of industry

Before he became a university lecturer, Professor May held management positions in the automotive sector that took him all the way to China. What he discovered there still shapes his thinking to this day: “It was impressive just how far Chinese industry had already come by that time. I became acutely aware that it would take a fair bit of work to make sure Germany – a high-wage country – could stay competitive.” The CETPM, which he founded, upskills workers from industry by providing university-level training courses, so it can drive forward operational improvements on its own initiative. The ultimate aim is to bolster the success of German industry and thus play a part in safeguarding the standard of living in the country.

Some of the issues addressed by events staged at the CETPM include operational excellence, lean management, Six Sigma and, of course, Karakuri/LCA. The CETPM has been collaborating successfully with item on this particular subject for many years. Professor May and Stefan Armbruster, Product Manager and lean expert at item, regularly host a joint Karakuri/LCA seminar. Together, they have already trained a great many specialists in Karakuri/LCA who have gone on to get things moving in their companies – quite literally. “We build Karakuri/LCA applications exclusively with item. It is quite simply the best system. We have been working with item for several years and with great success. We used to work with a different system, so I can say that without any reservations and speaking from personal experience,” emphasizes Professor May.

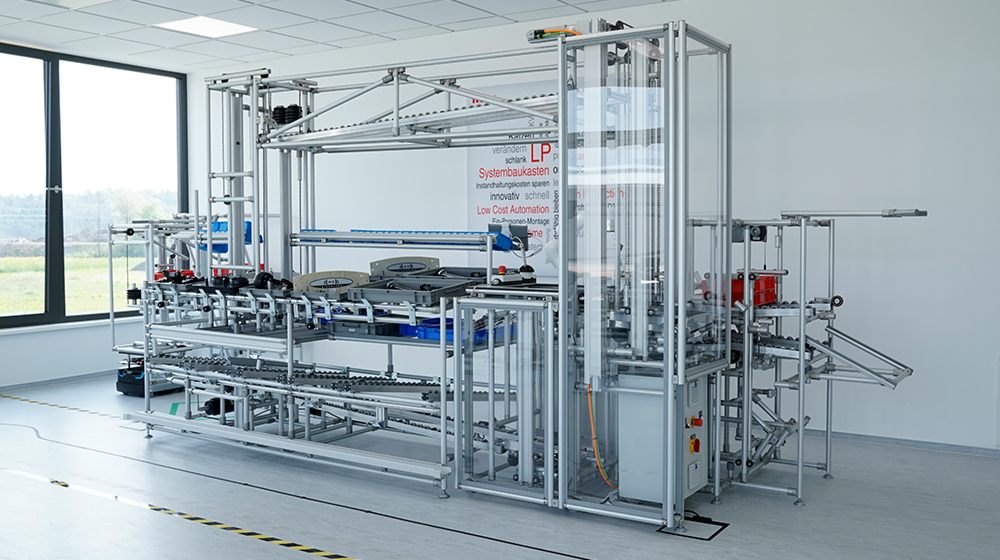

Both combinations side by side – Karakuri/LCA with an autonomous mobile robot (left) and with a robot solution incorporating a cobot (right).

Karakuri/LCA plus robot solutions – a winning combination for automation

Due to their low procurement costs, simple programming and flexible implementation options, collaborative robots (cobots) are becoming increasingly popular. The best of both worlds are brought together, as Professor May explains: “The strengths of cobots, such as endurance, reliability and repeatability, combine with the decision-making capabilities, flexibility and skill of human workers.” This collaboration between human and machine has already been working to good effect for a number of years, although it is not standard practice for the two to work hand in hand. Often, cobots take over the ergonomically unfavorable and monotonous work such as palletizing and machine loading. That frees up their human colleagues for other jobs. What’s more, suitable robot solutions can compensate for capacity shortfalls caused by the lack of skilled workers.

However, the strength of cobots is limited, which means they can only move around small load carriers to a limited extent, for instance. “Combining robot solutions with Karakuri/LCA considerably expands the potential uses for robotics, and vice versa. It’s a real win-win solution,” says Professor May. This is demonstrated by an application at the CETPM’s factory for the future, where visitors can watch numerous examples of innovative automation solutions in action. The application in question is centered around a cobot from the xArm range manufactured by UFACTORY. It fills small load carriers, before pressing a switch and lever and pushing an element forward to set the full SLC on its onward journey and bring in the next one. Once the relevant mechanisms have been actuated, everything runs automatically, thanks to elements such as slopes, rollers and a lift system.

Making even better use of autonomous mobile robots (AMRs)

Besides cobots, autonomous mobile robots (AMRs) are also among the rising stars of the automation universe. Although there is some debate about the differences between AGVs (automated guided vehicles) and AMRs, the benefits of AMRs are clear. Since they do not rely on markings, and use laser scanners to process a map of their surroundings instead, they can be introduced quickly. Thanks to artificial intelligence, they can distinguish between a permanent obstacle (e.g. a rack) and a temporary one (e.g. a person) and make decisions accordingly. As a result, they are able to expertly navigate obstacles. When fitted with suitable superstructures, they can carry out useful tasks, such as in intralogistics automation. “AMRs offer a great number of benefits, and technological progress means they are becoming an increasingly accessible option, too,” says Professor May.

Up till now, many AMRs have often only transported a single load carrier at a time. Loading and unloading has also been a complex affair, with conveyor belts, robot arms and similar systems needed to achieve automation. This is where Karakuri/LCA offers the ideal solution: “Here at the CETPM, we realized that you can make excellent use of Karakuri/LCA mechanisms to load and unload AMRs,” says Professor May. For instance, the kinetic energy of an autonomous mobile robot can be used to lift, lower or remove load carriers. Not only does such a solution save on costs – because the outlay on materials is much lower compared to conventional automation – but it also saves on electricity and thus cuts CO2 emissions because it does not rely on electrical power. If several load carriers are stacked on an AMR, they can be automatically unstacked by a Karakuri/LCA frame. This means more materials can be moved in the same amount of time. That opens up impressive opportunities and leaves us wondering what the CETPM will come up with next.

An AMR finds its own way to its destination and loading and unloading is equally automatic thanks to the frame, which is based on Karakuri/LCA principles.

Are you interested in fascinating reports and innovations from the world of lean production? Then we have just what you’re looking for! Simply subscribe to the item blog by completing the box at the top right.