An interview with Daniel Alvarez, item Design Engineer

Before joining the item Mexico team, Daniel Alvarez already had 10 years of experience in mechanical design, although in different industrial sectors. His main challenge at the start of his career at item was to become familiar with the wide variety of item products. Fortunately, the teamwork made the process flow naturally. Daniel says, “there is learning every day, since we always have to find the best way to materialize our client’s ideas, balancing simplicity with creativity”.

Alvarez’ position as Resident Engineer allows him to get to know clients directly, which – for Daniel – means a great opportunity to better understand the needs of clients and find the best way(s) to move projects forward. During his year and a half with item Mexico, Daniel believes one of his greatest achievements has been reinforcing the confidence that people have in the item brand.

Why did you choose engineering?

Because I always liked mathematics, and in engineering I knew I would have the opportunity to use it as a tool for practical applications.

What does it mean to you to be part of the item engineering team?

For me, it represents the opportunity to create and develop in the field that I am passionate about, which is mechanical design, since it is constantly required to create new specific solutions for each client. It also represents the opportunity to belong to a first-class organization, recognized globally for the quality of its products and services.

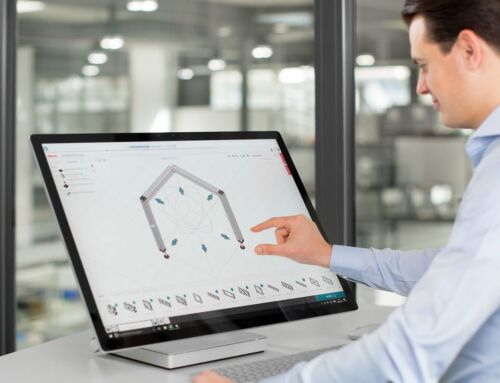

What do you think of digital engineering?

Digital Engineering is undoubtedly a concept that has been growing within the industry in general, since nowadays practically everything can be controlled from electronic devices, and it is necessary to be part of these advances in order not to fall into obsolescence.

How is digitalization changing the world of engineering?

It has increased the efficiency in the development of engineering projects For example, before, making a plan by hand took several hours (or even days), and if a mistake was made the plan was left with a record of the corrections, sometimes generating confusion; on the other hand with the use of digital tools making plans is much easier, and the engineer can concentrate on the creative part, and invest a smaller amount of time in the clear transmission of his ideas to the rest of the team involved in the project.

What are the benefits of digital engineering?

Efficiency, process standardization, error reduction, creative freedom, the possibility to simulate processes before implementation.

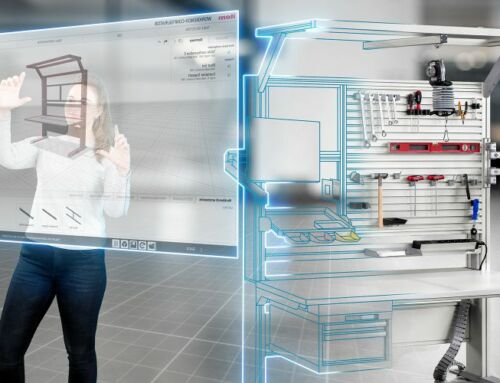

Where is the industry going with the digital change?

Towards more efficient production systems, with greater adaptability to changes and better control over the variables that affect all processes.

What challenges are posed by the digital change?

Keep up to date, as the industry is constantly changing. You also must know how to choose the right tools, as the range of possibilities is very wide nowadays.

How do you think item is handling with this change?

From my point of view, item handles the the changes of the industry at a global level very well, since it is constantly innovating both in its product catalogue and in the digital tools it offers to its clients and collaborators.

How did digitalization change design work and what are the benefits?

There are several digital tools that speed up the design process, such as the use of part libraries, standard templates for drawings, assemblies, and design parameterization, among others. In addition, the possibility of carrying out movement simulations or stress analysis makes it possible to validate a design prior to manufacture, which translates into savings in the manufacture of prototypes.