How it all began: From two-man firm to worldwide success story.

A new sales and production centre in Piepersberg, the recently opened item site in Hanover (which is also home to our Lean Factory) and not forgetting the innovative developments in digital engineering – a lot has happened at item in recent years. So it seems like the perfect time to take a minute and look back at the history of the MB Building Kit System. After all, besides being fun, delving into the past can teach us a lot, as company timelines such as ours often show just how profitable a long-term outlook can be. For item, it all started in 1973. Gerrit Pies and Wolfgang Rixen became friends whilst working together in the design office of a renowned mechanical engineering company. Not long after that, the two perfectionists decided to set up their own design office. Back then, the two-man company was still named “Rixen & Pies GbR” but unofficially everyone was already calling it “item” – an abbreviation of “industrial technology and mechanical engineering” in German.

Starting out in Solingen

In their very first office on a small street in Solingen, Pies and Rixen could often be found toiling away late at night. During the day, whilst one continued working as a design engineer, the other set about putting together quotations and drawings. At the heart of it all, item began as many start-ups do today. It didn’t take long before the partners made a name for themselves as designers and engineers of their independently distributed specialist machinery and in 1976, the company was officially renamed “item”.

Two years later, the business relocated to new premises with an on-site assembly workshop in the north-west of the city. New recruits joined the team and the company was more determined than ever to make its specialist machinery even more versatile and efficient. item was quick to adopt a workstation from Siemens, including a monochrome monitor and dot-matrix printer, and used it for all business correspondence, invoicing and order processing. The electrical engineering department was equipped with the latest technology, too, this time in the shape of programmable logic controllers (PLC).

The inspiration for the MB Building Kit System

It was one of those strange quirks of life that saw the company get serious about aluminium for the first time: Another passion of the two founders – cycling – led them to acquire a brief to develop and produce a bike rack primarily built from aluminium components for a customer. item had the necessary material produced in an aluminium press shop. As the project developed, the founders gradually realised the potential of the extrusion process. They experimented and created Profiles 40×40 and 80×40, which would later become the basic profiles for the MB Building Kit System. The new screw attachment principle using the aluminium building kit system profiles revolutionised the process of building expensive and time-consuming steel frame constructions.

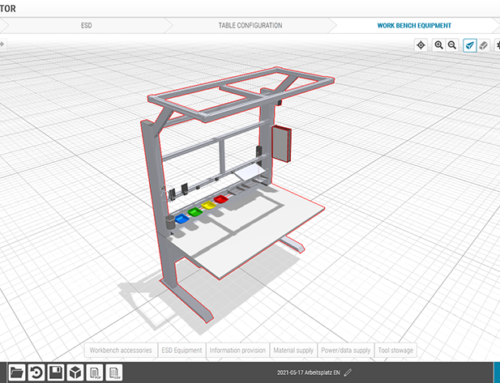

The time for a universal profile system made from aluminium had finally come. The first version was launched in 1980. To begin with, experts were sceptical about the idea but the form and functionality of the system – comprising initially seven basic profiles, a number of fasteners and functional elements and the first accessories – quickly won them over. As all constructions could be continuously adapted and, where required, redesigned from scratch, the system was already fully compatible with the then-new CAD technology. With its modular design, the MB Building Kit System laid the foundations of digital engineering.

Growing success abroad

item concluded its first distribution agreement for the MB Building Kit System with a partner company back in 1984. At the start of the 90s, item began successfully collaborating with distribution partners in Hungary, Slovenia and Poland. Then, in 1992, the first wholly owned subsidiary outside Germany was set up – item Italia. item continued to bolster its position on a regional scale, too, and founded eight distribution centres for the MB Building Kit System. Today, this figure stands at eleven. Slowly but surely, item became a global company – the USA was added to the list in 1997, followed by Australia and Africa just two years later. Nowadays, item solutions are available on all five continents. Besides setting up wholly owned subsidiaries in Switzerland and Poland, subsequent milestones notably include opening item International America LLC and item China.

Want to keep up to date with everything that’s going on in the world of item?

Simply subscribe to the item blog by completing the box at the top right!