There is no avoiding digitalisation in mechanical engineering – that much is clear now. There is a whole lot of potential to tap into, but of course there are challenges, too.

The biggest challenge associated with digitalisation is also the first one that has to be overcome – getting off to an early start. Companies that have been hanging back should act now. Ultimately, digitalisation is a gradual process that takes several years and can’t be achieved overnight. That means it’s also difficult to make up lost ground when you’re lagging behind. Companies that don’t yet have a digital strategy should face up to the challenge and start working on one now, before the competition is out of sight. All the same, companies shouldn’t feel forced into pursuing digital transformation – they need to be aware of the added value and new opportunities that digitalisation opens up, too.

Rolling out a digital strategy – from the boardroom to the factory floor

Before a company can start changing, it is important to differentiate between the forms that digitalisation can take. On the one hand, digitalisation can mean increasing operational efficiency. That involves using digital infrastructures, technologies and tools to optimise internal processes while leaving the fundamental business model untouched. On the other hand, digitalisation can be understood as the systematic realignment of the company’s business model. In the case of mechanical engineering, that could conceivably mean creating a marketplace for engineering data. That is why a company ought to specify what digitalisation actually means for its own operations before starting to develop its digital strategy.

As a logical consequence, digitalisation should be understood as a company-wide strategy and therefore should be driven by the management team. It can be useful to specify or appoint a Chief Digital Officer (CDO) to take responsibility for developing and implementing the digital strategy. However, while it is essential to ensure the management team is on board with digitalisation, that doesn’t mean the rest of the workforce can simply be left to get on with things. The ability to cope with change, social skills and IT expertise are all becoming ever more important due to digitalisation, meaning companies face the added challenge of providing appropriate basic and additional training. Having a well-developed culture of continuous learning is therefore crucial to the success of a digitalisation process and the development of new, digital business models.

Digitalisation is a must

From training and in-house processes to business models, there’s no avoiding the digital revolution in mechanical engineering. Our white paper brings you bang up to date.

Diverse challenges as part of a digital strategy

Given all the technical challenges involved in a digital strategy, it can be all too easy to lose sight of aspects such as innovation and creativity. However, it is crucial to nurture the potential of creative staff. There are various structural measures that can be used to achieve this, such as in-house innovation labs. These give specially selected staff the space and freedom they need to come up with original solutions. Even small, seemingly absurd ideas can go on to become something really big, as the success of countless start-up companies has proven. What’s more, companies should consider establishing a dedicated department for future growth.

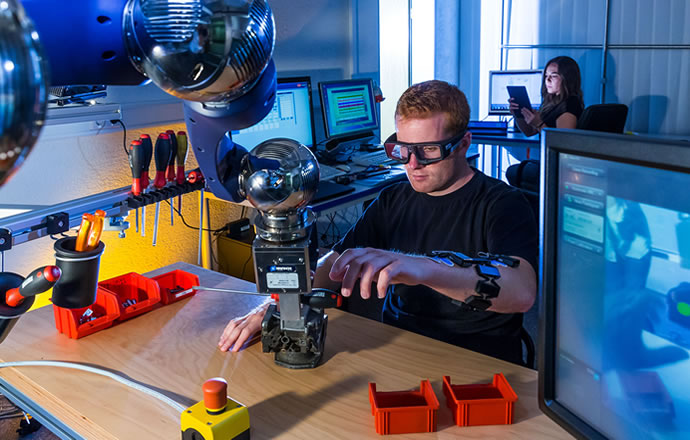

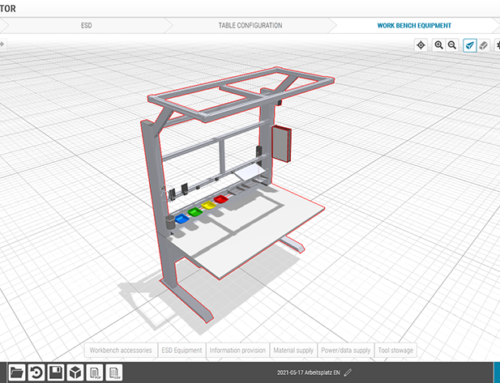

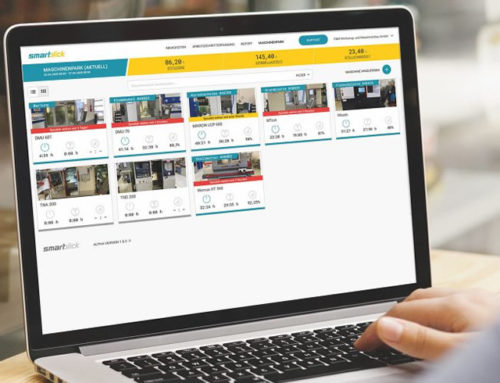

Technical infrastructure and equipment is always expected to keep pace with the abilities of the workforce, but the same can’t be said in reverse. According to the “Digital Economy Monitoring Report 2018” published by Germany’s Federal Ministry for Economic Affairs and Energy (BMWi), the share of mechanical engineering companies where the entire workforce uses digital infrastructures is just 41 percent. This statistic is all the more disappointing considering the benefits such infrastructures bring. For example, flexible work benches promote productivity by allowing any staff member to log into them with their own account. Another BMWi monitoring report (“Digitalisierungsprofil: Maschinenbau 2018”) indicates that the biggest obstacle to digitalisation in mechanical engineering could be the lack of broadband networks. According to the report, 68 percent of mechanical engineering companies hold this view, which is an above-average share compared to the commercial sector as a whole (43 percent). Some 46 percent of mechanical engineering companies also believe digitalisation takes up far too much time, while 41 percent cited inadequate IT security as an obstacle.

More challenges from big data

The volume of customer-related data being held by companies is also growing, not least due to digitalisation. This expansive and sometimes unstructured pool of data is generally referred to as “big data”. The potential harboured by volumes of data like this is huge – even though most companies actually analyse only a small proportion of it. Big data poses two clear challenges for companies. Firstly, they need to work out a strategy for structuring and analysing the data that is collected. After all, from a long-term perspective, companies that don’t leverage the opportunity to evaluate data they have collated and use it to their advantage will fall noticeably behind their competitors.

The second challenge associated with big data concerns data protection. Data that has been collected cannot be stored indefinitely. What’s more, before they can analyse data in any automated process, companies need to obtain the explicit permission of the individual whose data is to be collected and processed. Ideally, data that is being collected for analysis purposes will be completely anonymised before it is even saved. This ensures the stipulations of the General Data Protection Regulation (GDPR) are met and minimises any legal risks that could be associated with any loss of data, for example. All in all, big data offers a great deal of potential, but can only be utilised safely and securely with the right expertise and plenty of planning.

Are you interested in digitalisation and what the future of mechanical engineering will look like?

Then we have something that might just help! Simply subscribe to the item blog by completing the box at the top right!