One of the key challenges in digitalisation is developing new business models.

There are two aspects to digital transformation. It covers both the digitalisation of existing internal company processes and the adaptation or modification of business models. Many mechanical engineering companies are still hesitant when it comes to the latter. But they’re not alone in this. As Germany’s digital association Bitkom found out in its study “Digitalisierung der Wirtschaft” (“Digitalisation of the economy”, German only), just one in four of the companies surveyed is investing in new business models. Finance is certainly a contributory factor, and it is true that the optimisation of internal processes is already firmly anchored in mechanical engineering, particularly due to the widespread use of lean production methods. All the same, keeping things exactly as they are because you’re doing well at the moment is not an option. However, which new business models should mechanical engineering companies consider? And how exactly do you go about developing such a digital business model?

Digital services and platforms for mechanical engineering

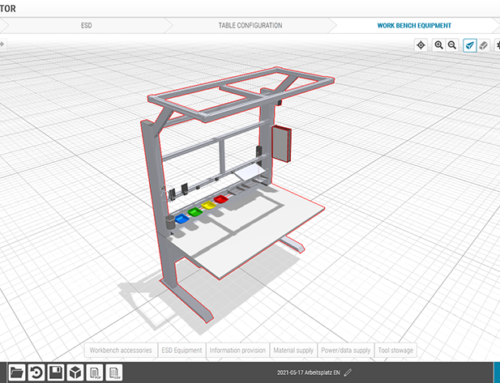

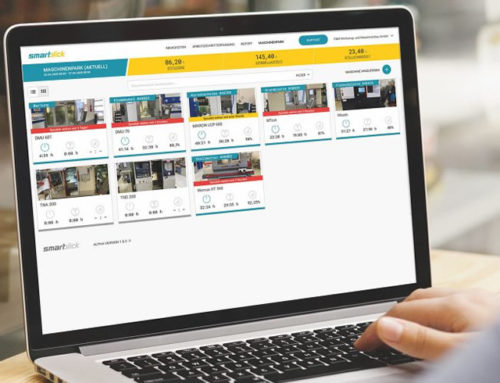

It goes without saying that there are no one-size-fits-all answers. Nevertheless, successful ideas from other sectors are already being adopted in the mechanical engineering sector. Predictive maintenance as part of the Industrial Internet of Things is a prime example. This involves continuously transmitting data from a machine so that its performance statistics can be permanently monitored. The key benefit is that even the slightest deviations in the data can help root out potential defects. Two things are typical of business models relating to predictive maintenance – firstly, there’s the networking aspect and, secondly, the service side. Companies don’t just deliver a piece of machinery, they also provide location-independent maintenance.

Looking at this scenario from a broader perspective, there is another important factor to bear in mind, which is that solutions based on the Industrial Internet of Things can be offered on platforms. Even if the term “platform economy” might not mean much to you right away, you probably come across it every day. Apple, Airbnb and Amazon are all digital platforms. They act as intermediaries – that is to say, they connect two or more market players with each other. When several companies come together in this context they form a “business ecosystem”. A number of different approaches are important when it comes to new business models in mechanical engineering. These relate primarily to marketplaces for services and goods. As a general trend, it is to be expected that services will generate increasing volumes of sales in the mechanical engineering sector.

The path to new business models in mechanical engineering

The question now is how mechanical engineering companies can start developing new, digital business models. Again, this is a skill that can be learned – Business Model Innovation. The Business Model Navigator developed by the University of St Gallen is one of the best known models for this discipline. While designing it, the researchers discovered that 90 percent of the business models examined weren’t new at all – in fact they were simply adaptations of existing models or new combinations of established elements. The Business Model Navigator can be used to both evaluate current business models and create new prototypes. The following questions offer guidance:

• Who are the target customers?

• What is promised to the customers?

• How is the product or service created?

• How exactly is the value created?

On top of this, 55 typical patterns for successful business models have been identified. The Business Model Canvas has become extremely popular with start-ups in particular, as it is especially well-suited to laying out an overview of business models on a single page. The range of categories stretches from aspects such as key partners, activities and customer relations to channels and sources of income. However helpful these methods may be, the growing importance of the platform economy means they are not sufficient for the more complex new business models in mechanical engineering. Technical committee 7.23 of the VDI/VDE Society for Measurement and Automatic Control (VDI/VDE-GMA) has therefore developed its own VDI Industry 4.0 canvas. This gives particular consideration to the suitability of potential platform partners, which can be assessed in fine detail based on the criteria of value contribution, value drivers, reliability and integration. In its most developed form, it gives rise to a total of three interconnected canvases.

Are you interested in digitalisation and what the future of mechanical engineering holds?

Then we have something that might just help! Simply subscribe to the item blog by completing the box at the top right!