Lean Production System: Lean in Real Time

The values of quick-connect progressive assembly material handlers

In manufacturing today, we talk a lot about “workflow”. The term “workflow” can be described as a sequence of connected steps with the idea of creating a streamlined process without delays or gaps between each of the steps.

Continuous improvement, or Kaizen, is the philosophy or practice of improvement of the manufacturing process. Material Handling Systems (MHS) are a fundamental part of both workflow and Kaizen in manufacturing. MHS involves the movement, storage, control and protection of material or product as it moves through the manufacturing process.

Another important factor in material handing is manufacturing space, the cost of which has steadily increased over the years. This, plus the ever-increasing cost of utilities, has pushed manufacturers to make the best use of space and resources in an effort to lower overhead costs.

The Role of Progressive Assembly

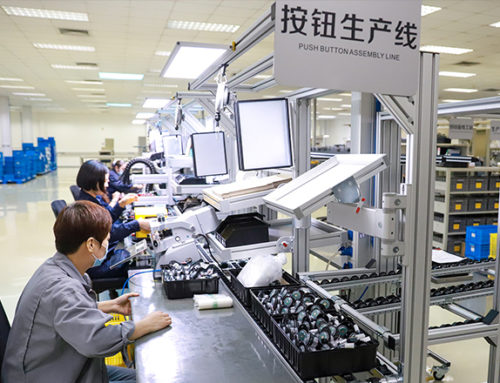

The role of “Progressive Assembly”, or in some cases “Progressive Packaging”, is an integral part of workflow. The use of an assembly line to add parts to a product in a sequential manner has been in use for over 100 years. This concept minimizes the movement of workers, which in turn increases production and safety.

There are three key principles to progressive assembly:

- Tools and personnel need to be in a sequence of operation so that each component will travel the shortest possible distance.

- Material carriers are employed so that when a step is completed the worker merely returns a part to the same place. Ideally, gravity should move the part to the next step or worker.

- Sliding assembling lines are used so that parts can be delivered conveniently to the next step.

Progressive Assembly concepts have been a boon to the safety and improved working conditions for employees. Using progressive assembly means workers are not required to lift heavy parts. This eliminates the need for stooping or bending, which greatly reduces the risk of injury.

The Impact of Lean Manufacturing

Lean manufacturing creates value by expediting production while minimizing waste. In other words, preserving value with less work. In many cases this means using the same space to produce different products.

Manufacturers that require the change of materials or parts to its process find it difficult to use the same material handling systems for differing product lines. Thus, instead of adding additional manufacturing space, the lean way of manufacturing is to adjust the material handlers and/or the progressive assembly lines.

How can manufacturers quickly readjust their processes to match their workflow?

This brings us to the value of using a quick-connect material handling product made from non-machined connections which join in a simple yet powerful way.

Tubular building kits are both flexible and strong. Additionally, in just a few minutes they can be assembled to meet the needs of workflow. The tubular design requires only a few quick connections such as angle, end and T connectors. These can easily be assembled into material handling tools such as tables, workbenches, shelving, trolleys, mobile shelving and material provision racks.

Lightweight, but strong, the Lean Production System (LPS) from item is a prime example. The load bearing of this quick connect aluminum tubular system is impressive.

Manufacturing facilities typically set up a small on-site area where tubular components can be assembled. Each assembly area has a small stock of tubes, connectors and various material handing items, such as bins or castors. Tools should include a tape measure, hacksaw, hex keys, sketch paper and pencils. A binder to document previous designs for quick reference is a good idea, as well.

Conclusion

Successful manufacturers are changing the way they approach workflow.

Instead of creating inflexible workflow systems, they employ more creative and efficient ways to move products. The ability to modify and create unique material handlers is the key to meeting the demands of our ever-changing manufacturing environment.

.

.

Adapted from an article originally written by Larry Mainers.