Retrofitting – making the old new again

When a plant becomes outmoded or faulty, buying a whole new one isn’t always the most cost-effective solution.

Carrying out a retrofit, i.e. upgrading an existing plant or machine, is a striking alternative that is proving very popular. To put it in more specific terms, retrofitting involves incorporating new components into an “old” solution to bring it up to the state of the art. The end result is usually a clear improvement in efficiency, error avoidance and speed. What’s more, if you’re smart about it and adopt a step-by-step approach, you can complete an optimisation/modernisation project like this without significant downtime.

The benefits of retrofitting

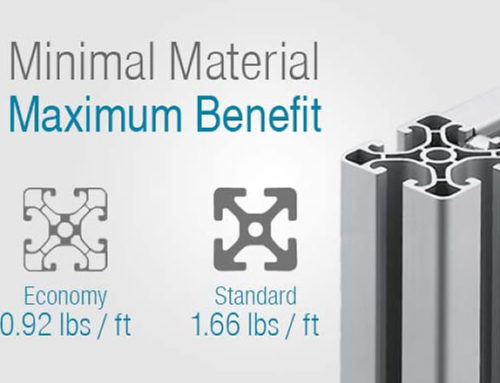

The general tendencies in mechanical engineering are conducive to retrofitting. For example, the mechanics of a plant will often continue to function perfectly even after a long service life. Far from being old scrap, they offer the perfect framework for applying the latest methods in control, automation and drive technology. This approach produces a promising hybrid of tried-and-tested technology and cutting-edge solutions.

However, there are more advantages to retrofitting besides just technical factors. If you compare the costs for a new acquisition with those for a retrofit, the latter can be between 40 and 80 percent lower. What’s more, under certain circumstances, only the attentive optimisation of an existing plant can enable it to achieve its full potential. However, it’s important not to generalise too much when considering the above advantages. After all, everything depends on the condition of the specific plant in question. Nonetheless, a retrofit should always be considered as an alternative to a new procurement.

When is retrofitting worthwhile?

The above-mentioned cost factor is just one of many reasons why retrofitting can be a good idea. Even if your aim is to boost production output or product quality, this approach can help you achieve a great deal. Companies can hit real trouble if urgently needed spare parts are no longer in production, but retrofitting can be an effective solution to precisely such a dilemma. What’s more, downtime and maintenance costs can be significantly reduced through this approach and employees don’t need to spend time familiarising themselves with completely new systems.

In addition, retrofitting can be a useful answer to questions such as: What do I do if occupational health and safety guidelines change? What do I do if the user friendliness of my existing machinery no longer meets current standards? How suitable is my plant for integrating IT?